Shading Jig

Structure

The Shading Jig used in Shading Calibration (Basic Adjustment) for the SC-P8500DM series/SC-T7700DM series/SC-T5700DM series comprises the following four types of parts. When carrying out Shading Calibration (Basic Adjustment), three sets of this jig are required.

| Name | Code | Quantity required in order to carry out Shading Calibration | Overview |

|---|---|---|---|

| Shading Jig (Completed) | --- | 3 |

|

| Shading Jig, Weight, Assy | 9101662 | 3 |

|

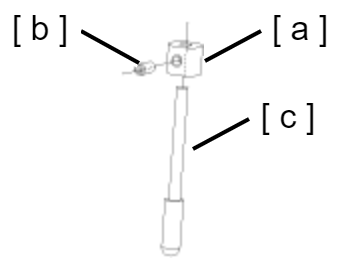

| Shading Jig, Pin, Assy | 9101663 | 6 |

a: Nut b: Fixing screw c: Pin |

| LFP SPONGE SHEET JIG | 1798963 | 3 |

|

| LFP SHADING WHITE SHEET JIG | 1798065 | 3 |

|

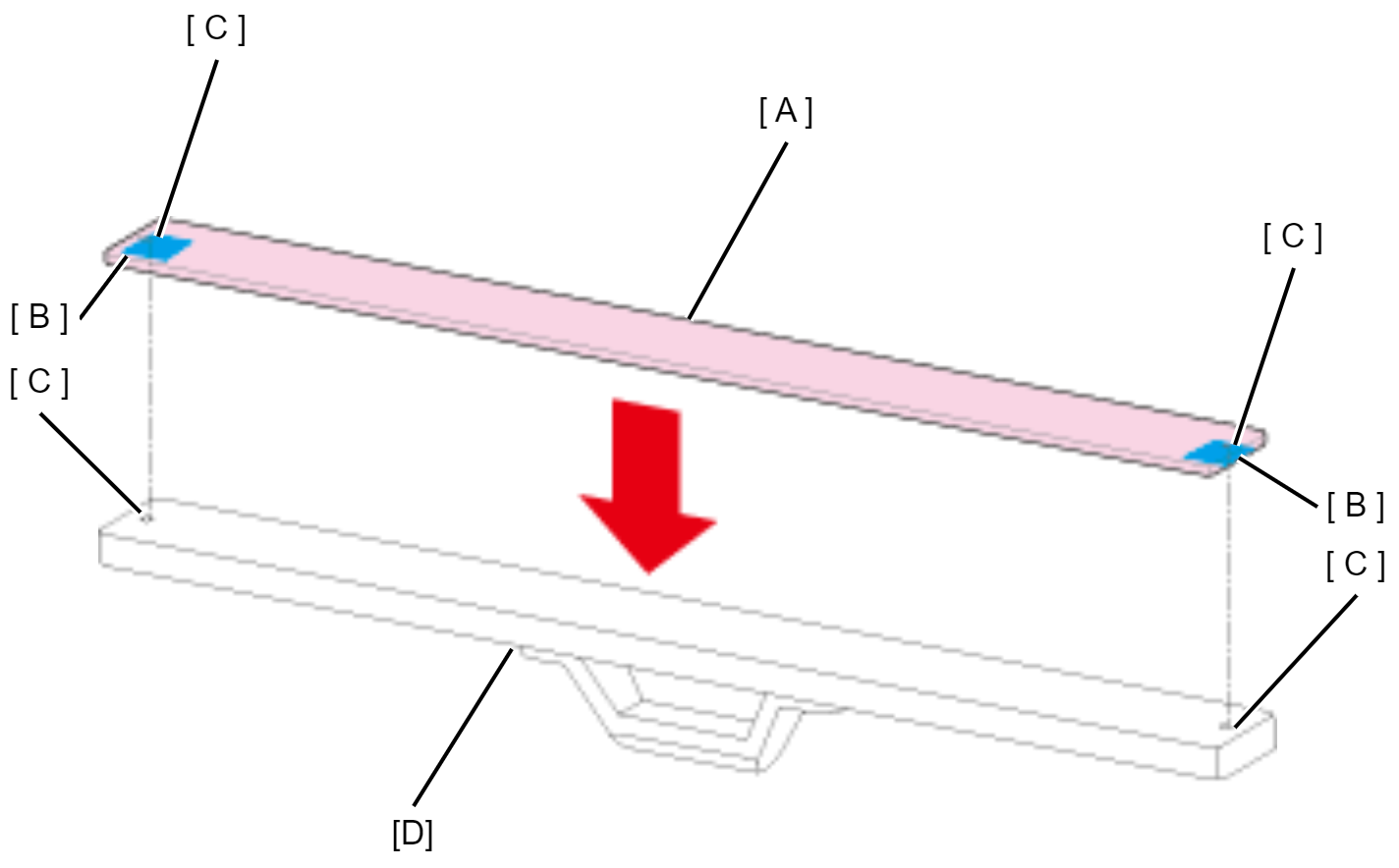

Jig-Making Procedure

- Remove the backing from the double-sided tape (B) affixed to the LFP SPONGE SHEET JIG (A), align the holes of the Shading Jig, Weight, Assy (C) with the holes (D) of the LFP SPONGE SHEET JIG, and affix.

Caution / 注意

Caution / 注意When affixing the sponge sheet, do not press and crush the sponge.

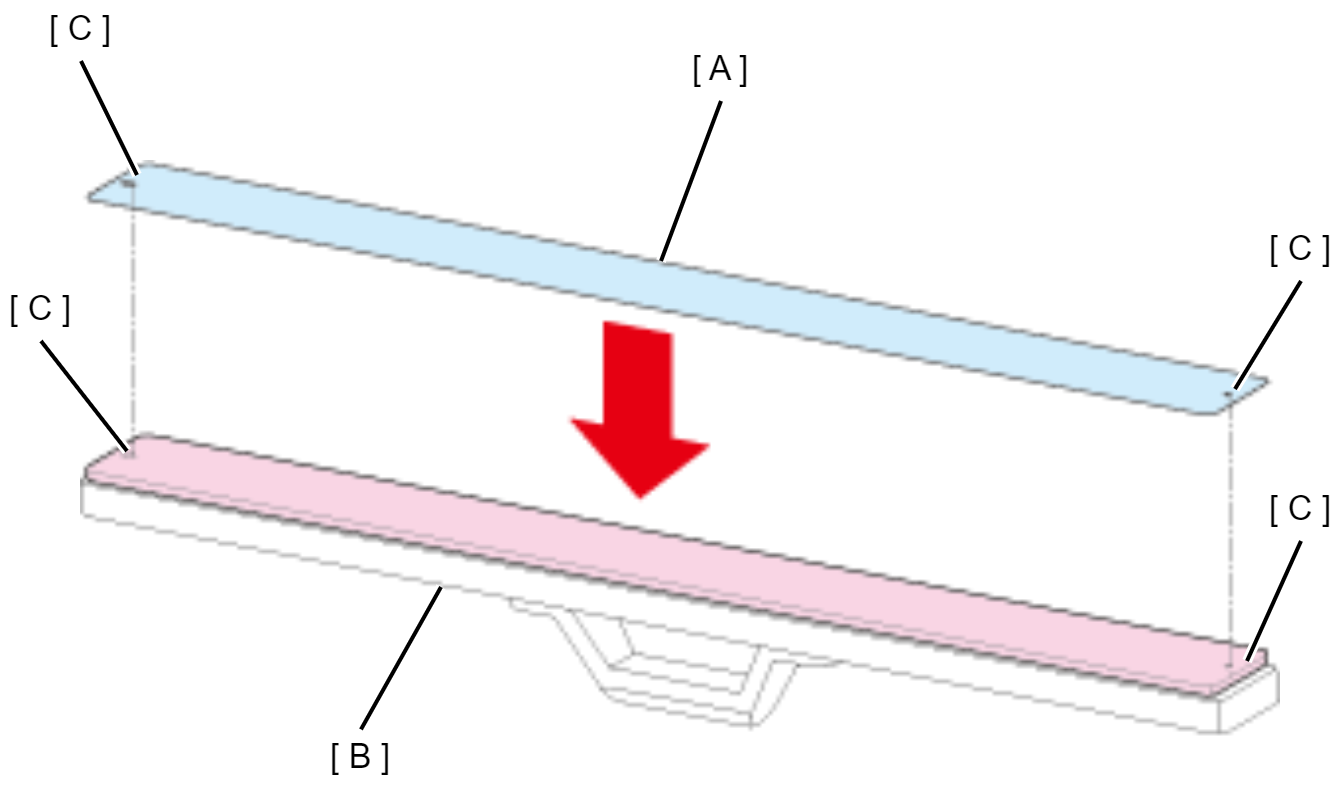

- Place the LFP SHADING WHITE SHEET JIG (A) in line with the position of the LFP SPONGE SHEET JIG (B) holes (C).

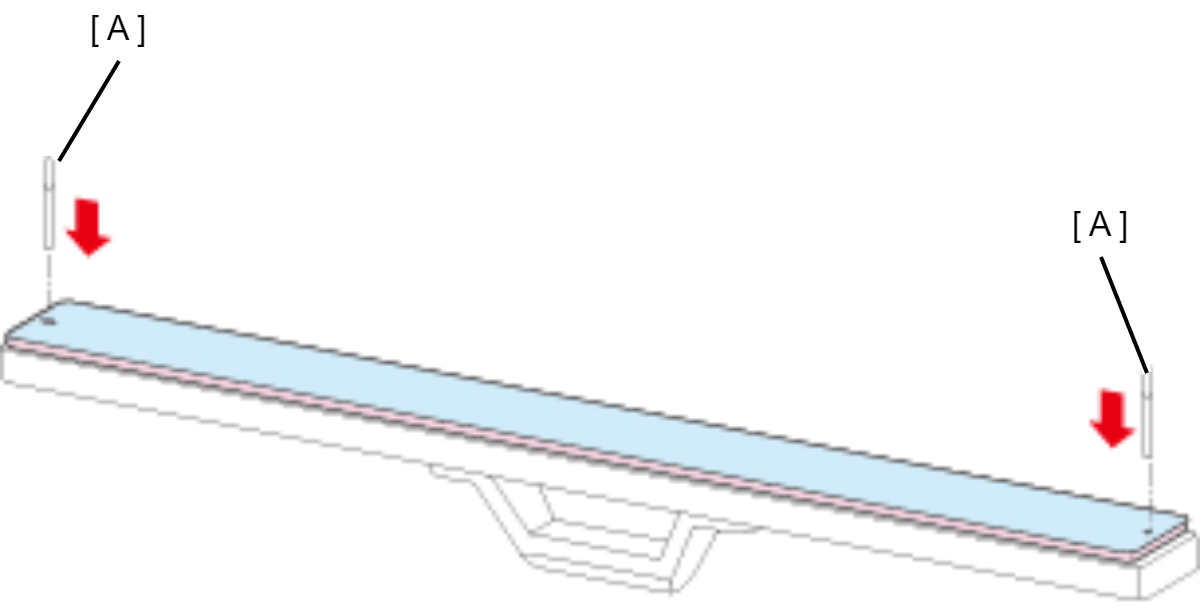

Insert the Shading Jig, Pin, Assy pins (A) in the holes.

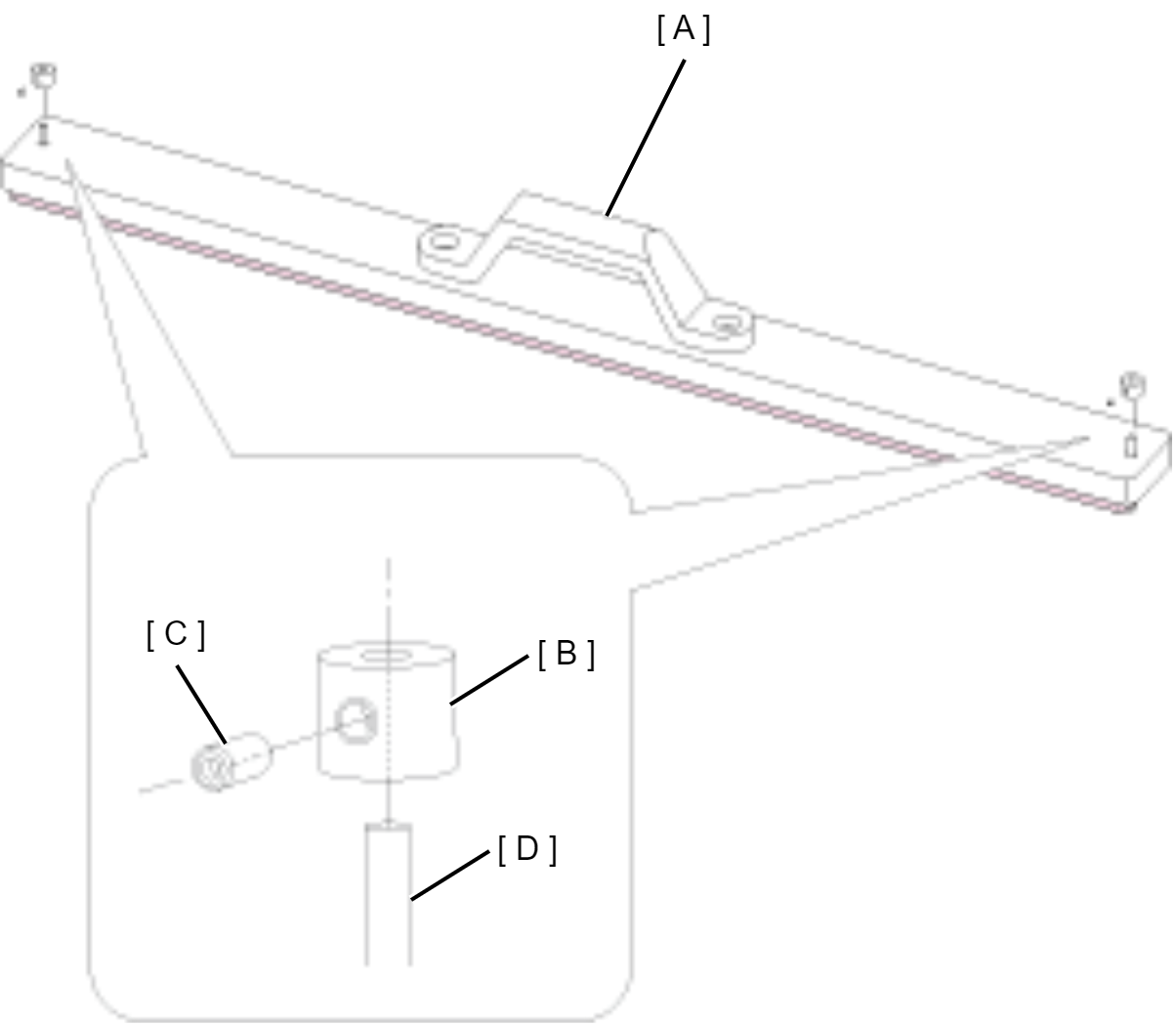

Secure the Shading Jig, Pin, Assy (A) nuts (B) and fixing screws (C) with pins (D).

Jig Storage

If the LFP SHADING WHITE SHEET JIG (white sheet) is soiled or folded, then appropriate adjustment will not be possible.

When storing the Shading Jig, ensure that the LFP SHADING WHITE SHEET JIG (white sheet) is not soiled. (Remove at each use, and store separately in a bag)

If the LFP SHADING WHITE SHEET JIG (white sheet) is soiled or folded, then replace with a new part.