- SC-P8500/SC-P6500/SC-T7700/SC-T5700/SC-T3700 Series Service Manual Rev.E

- Product Descriptions

- Structure/Operation Principle

- Structure/Operating Principles

- Scematics (Block Diagrams) / Wiring Diagrams

- Block Wiring Diagram

- Connection Diagram

- Housing

- Electric Circuit Components (1)

- Electric Circuit Components (2)

- Electric Circuit Components (3)

- Electric Circuit Components (4)

- Electric Circuit Components (5)

- Carriage Mechanism/Ink System Mechanism (1)

- Carriage Mechanism/Ink System Mechanism (2)

- Carriage Mechanism/Ink System Mechanism (3)

- Paper Feed Mechanism (1)

- Paper Feed Mechanism (2)

- Paper Feed Mechanism (3)

- Paper Feed Mechanism (4)

- Paper Feed Mechanism (5)

- Paper Feed Mechanism (6)

- Paper Feed Mechanism (7)

- Other Parts

- Harness/FFC

- Ink Holder (RIPS)

- Scanner (1)

- Scanner (2)

- Scanner (3)

- Scanner (4)

- Operation Sequence

- Installation and Setup

- Troubleshooting

- Overview

- Troubleshooting Work Flow

- Product Information Check Tool Utilization

- Maintenance Call (Bit Assignment Table)

- Troubleshooting

- Troubleshooting from Service Call

- Service Call Classification Table

- Service Call List

- 111X/112X (Sensor related error)

- 113X (CR related error)

- 12XX (PF related error)

- 14XX (Ink system related error)

- 151X (APG related error)

- 154X (Cutter related error)

- 166X (Fan related error)

- 16CX (Shutter related error)

- 1A3X/1AXX/1BXX (Head related error)

- 1FXX (CSIC related error)

- 300X (SOC related error)

- 5XXX (Ink leakage related error)

- 18XXX (Scanner related error)

- Others (Other board related error)

- Details of Service Call

- 001000 (Life End Error)

- 001114 (Sub Board Startup Error)

- 001115 (Sub-board Power Error)

- 00111D (1st Paper Supply Driven Home Position Detection Error)

- 00111E (2nd Paper Supply Driven Home Position Detection Error)

- 00111F (Shutter Home Position Detection Error)

- 001125 (CR Home Position Detection Error)

- 001128 (Cutter Home Position Detection Error)

- 001129 (PG Home Position Detection Error)

- 00112B (PF Driven Home Position Detection Error)

- 00112C (Intermediate Sub PF Driven Home Position Detection Error)

- 00112D (Paper Eject Driven Home Position Detection Error)

- 00112F (Paper Thickness Sensor Error)

- 001135 (CR Motor Disconnection Error)

- 001137 (CR Operation Prohibition Error)

- 001138 (CR Motor Overcurrent Error)

- 001139 (CR Motor Oscillation Error)

- 00113A (CR Motor Overload Error)

- 00113C (CR Motor Reversing Error)

- 00113D (CR Motor Driving time-out Error)

- 00113E (CR Motor Velocity Deviation Error)

- 00113F (CR Motor Lock Error)

- 001229 (PF Driven Roller Motor Oscillation Error)

- 00122A (PF Driven Roller Motor Overload Error)

- 00122C (PF Driven Roller Motor Reversing Error)

- 00122D (PF Driven Roller Motor Driving time-out Error)

- 00122E (PF Driven Roller Motor Velocity Deviation Error)

- 00122F (PF Driven Roller Motor Lock Error)

- 001249 (Sub PF Driven Roller Motor Oscillation Error)

- 00124A (Sub PF Driven Roller Motor Overload Error)

- 00124C (Sub PF Driven Roller Motor Reversing Error)

- 00124D (Sub PF Driven Roller Motor Driving time-out Error)

- 00124E (Sub PF Driven Roller Motor Velocity Deviation Error)

- 00124F (Sub PF Driven Roller Motor Lock Error)

- 001289 (Paper Eject Driven Roller Motor Oscillation Error)

- 00128A (Paper Eject Driven Roller Motor Overload Error)

- 00128C (Paper Eject Driven Roller Motor Reversing Error)

- 00128D (Paper Eject Driven Roller Motor Driving time-out Error)

- 00128E (Paper Eject Driven Roller Motor Velocity Deviation Error)

- 00128F (Paper Eject Driven Roller Motor Lock Error)

- 0012C9 (1st / 2nd Release Motor Oscillation Error)

- 0012CA (1st / 2nd Release Motor Overload Error)

- 0012CC (1st / 2nd Release Motor Reversing Error)

- 0012CD (1st / 2nd Release Motor Driving time-out Error)

- 0012CE (1st / 2nd Release Motor Velocity Deviation Error)

- 0012CF (1st / 2nd Release Motor Lock Error)

- 0012E9 (1st Roll Paper Motor Oscillation Error)

- 0012EA (1st Roll Paper Motor Overload Error)

- 0012EC (1st Roll Paper Motor Reversing Error)

- 0012ED (1st Roll Paper Motor Driving time-out Error)

- 0012EE (1st Roll Paper Motor Velocity Deviation Error)

- 0012EF (1st Roll Paper Motor Lock Error)

- 001309 (ASF Motor Oscillation Error)

- 00130A (ASF Motor Overload Error)

- 00130C (ASF Motor Reversing Error)

- 00130D (ASF Motor Driving time-out Error)

- 00130E (ASF Motor Velocity Deviation Error)

- 00130F (ASF Motor Lock Error)

- 001329 (2nd Roll Paper Motor Oscillation Error)

- 00132A (2nd Roll Paper Motor Overload Error)

- 00132C (2nd Roll Paper Motor Reversing Error)

- 00132D (2nd Roll Paper Motor Driving time-out Error)

- 00132E (2nd Roll Paper Motor Velocity Deviation Error)

- 00132F (2nd Roll Paper Motor Lock Error)

- 001418 (Pump Cap Unit Overcurrent Error)

- 001419 (Pump Cap Unit Oscillation Error)

- 00141A (Pump Cap Unit Overload Error)

- 00141C (Pump Cap Unit Reversing Error)

- 00141D (Pump Cap Unit Driving time-out Error)

- 00141E (Pump Cap Unit Velocity Deviation Error)

- 00141F (Pump Cap Unit Lock Error)

- 0014B0 (Cannot Print In Cleaning Mode Error)

- 0014C0 (Pump Cap Unit Position Detection Failure Error)

- 0014C1 (Pump Cap Unit Position Mismatch Error)

- 0014C2 (Flushing Box Lid Overload Error)

- 0014C3 (Flushing Box Lid Open/Close Error)

- 0014C4 (Ink System Maintenance Unit Position Correction Value Error)

- 001519 (APG Motor Oscillation Error)

- 00151A (APG Motor Overload Error)

- 00151C (APG Motor Reversing Error)

- 00151D (APG Motor Driving time-out Error)

- 00151E (APG Motor Velocity Deviation Error)

- 00151F (APG Motor Lock Error)

- 001545 (Cutter Motor Cable Disconnection Error)

- 001549 (Cutter Motor Oscillation Error)

- 00154A (Cutter Motor Overload Error)

- 00154C (Cutter Motor Reversing Error)

- 00154D (Cutter Motor Driving time-out Error)

- 00154E (Cutter Motor Velocity Deviation Error)

- 00154F (Cutter Motor Lock Error)

- 00166F (Suction Fan Lock Error)

- 00167F (Cooling Fan Lock Error)

- 0016C9 (Shutter Motor Oscillation Error)

- 0016CA (Shutter Motor Overload Error)

- 0016CC (Shutter Motor Reversing Error)

- 0016CD (Shutter Motor Driving time-out Error)

- 0016CE (Shutter Motor Velocity Deviation Error)

- 0016CF (Shutter Motor Lock Error)

- 001A20 (Head Fixed Position FL Timeout Error)

- 001A21 (Head NVT Timeout Error)

- 001A24 (Head Outbound Acceleration FL Timeout Error)

- 001A26 (Head Outbound Print Timeout Error)

- 001A27 (Head Return Print Timeout Error)

- 001A28 (Head Outbound Acceleration FL Print Timeout Error)

- 001A2A (Head Outbound Acceleration FLNVT Print Timeout Error)

- 001A38 (Transistor AMBIENT Temperature Error)

- 001A3A (Head Hot Error (Head))

- 001A39 (Head Fuse Error)

- 001A3C (VBS Overvoltage Error)

- 001A41 (Head Rank ID Input Error)

- 001A42 (Head Temperature Error (Head))

- 001A43 (Head Memory Read Error)

- 001A45 (Head Install Error)

- 001A46 (HCS Communication from Head to Main Board Error)

- 001A47 (Main Board Internal HCS Communication Error)

- 001A48 (HCS from Head to Main Board Error)

- 001A49 (Main Board Internal HCS Error)

- 001B00 (I2C Communication Time-out Error)

- 001F80 (Fuse Blow Error)

- 001F81 (EPC Check Error)

- 001F82 (Destination Outside Setting Range Error)

- 001F90 (SOC Operation Error)

- 001F91 (MR Data Error)

- 001FB9 (CS Rank Outside Setting Range Error)

- 001FC0 (ASIC Communication Error (Read) (CRCM 1))

- 001FC8 (ASIC Communication Error (Write) (CRCM 1))

- 003009 (AstrioC - AstrioP Communications Check Failure at Power ON)

- 00300A (ROM Version Check Failed When Power is Turned On AstrioP)

- 005001 (Ink Leak Error)

- 005002 (Ink Leak Error)

- 005003 (Ink Leak Error)

- 0186A1 (Document Feed Motor Overspeed Error)

- 0186A2 (Document Feed Motor Reversing Error)

- 0186A3 (Document Feed Motor Lock Error)

- 0186A5 (Document Feed Motor Overload Error)

- 0186A8 (Document Feed Motor Heat Error)

- 0186D0 (Scanner Non-connection Error)

- 0186D2 (Printer F/W and Scanner F/W Mismatch Error)

- 018701 (Scanner Paper Feed Flap Opening / Closing Motor Overspeed Error)

- 018702 (Scanner Paper Feed Flap Opening / Closing Motor Reversing Error)

- 018703 (Scanner Paper Feed Flap Opening / Closing Motor Lock Error)

- 018705 (Scanner Paper Feed Flap Opening / Closing Motor Overload Error)

- 018708 (Scanner Paper Feed Flap Opening / Closing Motor Heat Error)

- 018709 (Scanner Paper Feed Flap Failure Error)

- 018760 (Calibration Error)

- 018773 (Scanner SOC Communication Error)

- 018774 (Scanner SOC Connection Error)

- 018775 (OVP (Scanner Power Supply Cable) Connection Error)

- 018776 (Fatal Error Caused by Non-scanner Fatal Error)

- 202620/302620/0A3C (Wireless Board Failure Occurred)

- 203002/303002/0BBA (Optical Touch Panel Failure Occurred)

- 203201/303201/0C81 (PDL Board Failure Occurred)

- 205608/305608 to 205620/305620/15F4 (Internal SSD Failure Occurred)

- 205610/15EA (Internal SSD Failure Occurred)

- 205621/15F5 (Non-standard Internal SSD Connected)

- 208801/308801/2261 (TPM Board Failure Occurred)

- 256101/356101/17D5 (Main Circuit Board Watchdog Error Occurred)

- 256102/356102/17D6 (Main Circuit Board Watchdog Error Occurred)

- 256103/356103/17D7 (Main Circuit Board Watchdog Error Occurred)

- 256200/356200/DB88 (Main Circuit Board Failure (Overvoltage) Occurred)

- 256202/356202/DB8A (Head Drive Board Failure (Overvoltage) Occurred)

- 256203/356203/DB8B (In-printer LED Board Failure (Overvoltage) Occurred)

- 256205/256205/DB8D (Optional SSD/Bluenote (PS) failure (voltage drop) occurred)

- 256224/356224/DBA0 (Scanner Board Failure (Overvoltage) Occurred)

- 256225/356225/DBA1 (Main-B Circuit Board Failure (Overvoltage) Occurred)

- 256226/356226/DBA2 (CH83 Main-B Circuit Board Watchdog Error Occurred)

- 256234/356234/DBAA (Printer Power + 42V Voltage Drop Occurred)

- 256235/356235/DBAB (CRCM Board + 42V Voltage Drop Occurred)

- 308900 series (PCI-e related error code)

- Other than the above (Firmware Trouble Occurred (Debug Error))

- Troubleshooting from Problem Phenomenon

- Problem Phenomenon Classification Table

- Problem Phenomenon Overview

- Detail of Problem Phenomenon

- The nozzles are still clogging after cleaning.

- The nozzles are still clogging after cleaning. (Clogging due to thickened ink)

- The same nozzles are still clogging after cleaning. (Clogged nozzles (one or more) are not improved even after cleaning.)

- The nozzles are still clogging after cleaning. (Some nozzles are clogged. The same nozzles are always clogged but different nozzles may be clogged after cleaning)

- A large number of nozzles are clogged simultaneously, but they are improved after cleaning once. However, nozzles are clogged again after a while

- A large number of nozzles of either head 1 or head 2 are clogged, the nozzles are still clogging after cleaning.

- Some nozzles are clogged randomly.

- Horizontal or vertical lines look misaligned, become a double line, or become thick.

- Banding in the carriage movement direction (Horizontal banding).

- Banding in the paper feeding direction. (Vertical banding)

- Printed side is smudged or smeared with ink.

- The backside of paper is smudged or smeared with ink.

- Color or print density unevenness within a page or across pages.

- Media leading edge uneven density occurs.

- Blurred print

- Paper dust is attached or the traces of the rollers/nip appear.

- Cockling (uneven density due to paper wrinkling) occurs.

- Unevenness on the upper end part

- Not printed in either of outward path or inward path of CR movement

- During printing, printing stopped part way, and the power went off

- Printing (ink injection) stops during print operation.

- Partial printing is missing (short section)

- When printing, other than print data is printed with gradation

- Roll paper is not recognized during paper feed. (Paper feeding does not start as paper is not detected.)

- Paper in the manual bypass is not recognized (error code).

- The PW Sensor has failed and the paper size cannot be correctly measured. (Printing might be performed on the platen.)

- Paper is fed but does not arrive at the correct position

- Paper feed or ejection is abnormal. Paper end is determined even though media remains.

- Paper end is determined even though roll paper media remains.

- Paper is skewing.

- Actual margins differ from the specified margins.

- Media wrinkles during paper feeding

- Printouts are rippled.

- After Cutter Unit/Cutter Rail Unit replacement, media is not cut straight.

- Damage on printed surfaces (1)

- Damage on printed surfaces (2)

- Paper jams occur frequently

- When paper feeding: paper thickness error (920482) occurs.

- The printer is not powered/ It turns off immediately when the power is turned on

- Cannot access to the network

- The printer makes a strange noise when the CR is moving

- Ink is leaking

- The inside light is not on (head maintenance side)

- The inside light is not on (print side)

- Power light turns ON but LCD panel does not

- Stacker abnormality (does not extend, cannot be rewound, torn, etc.)

- The following message is shown on the panel, and doesn't disappear even after a power OFF/ON. "The TPM (security chip) is faulty. Either turn password encryption off, or initialize all printer settings. "

- The following message is shown on the panel, and doesn't disappear even after a power OFF/ON. "The TPM (security chip) is faulty, therefore the password encryption feature is unavailable. "

- The SSD cannot be used

- The LCD panel freezes on the "EPSON" screen

- Although there is no nozzle clogging, automatic cleaning starts

- The printer does not operate even though the program function is executed.

- "Media has been fed" error

- NVRAM Viewer does not start/File does not open

- The button used to open NVRAM Viewer is not displayed.

- The content displayed on NVRAM Viewer does not match the item names.

- The counter reset history and error history are not displayed on NVRAM Viewer.

- The color of head 1 or head 2 comes out completely as shown in the picture.

- Even if you execute paper feeding, there is a rattling noise and you cannot feed the paper.

- Wired LAN does not respond at all (LED does not illuminate even if you pierce the Ethernet cable, printer cannot be found, etc.)

- "Not an EPSON supported product" error

- Banding during scan or copy.

- Paper feed failure during scan or copy.

- Scanned image is skewed.

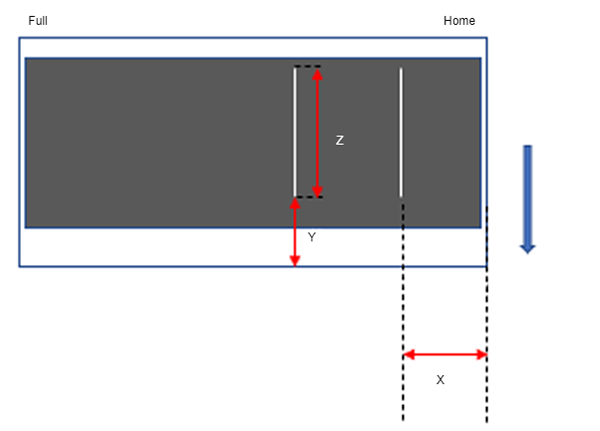

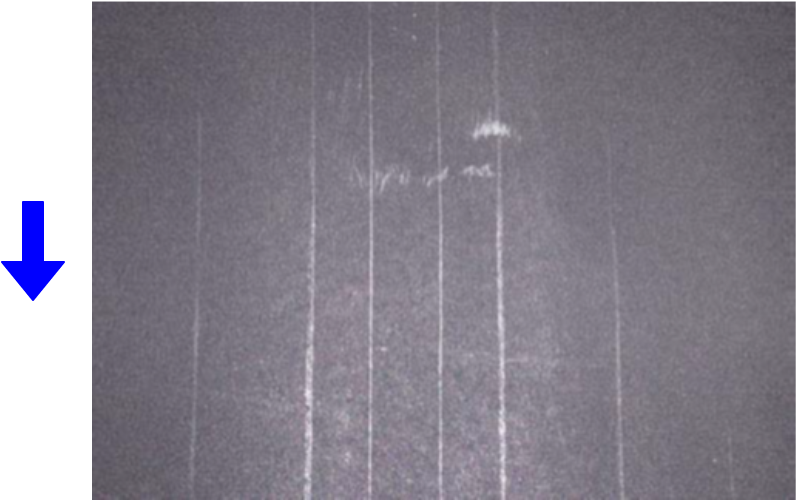

- Joins between CIS Modules are misaligned.

- Part or all of an image cannot be read.

- Scanned or copied image colors are not even.

- Scanned images are faint.

- Frequent paper jams during scan or copy.

- Paper folding during scan or copy.

- Troubleshooting from Service Call

- Resistance Values

- Fuses Positions

- The table for repairing the CH83 Main board

- Disassembly & Assembly

- Repair Work Overview

- Precautions

- Difference between models

- Disassembly Flowchart

- SC-P8500D series/SC-T7700D series/SC-T5700D series/SC-P6500D series/SC-P6500DE series/SC-T3700D series/SC-T3700DE series/SC-P6500E series/SC-T3700E series

- Housing 1/5

- Housing 2/5

- Housing 3/5

- Housing 4/5

- Housing 5/5

- Electric Circuit Components 1/3

- Electric Circuit Components 2/3

- Electric Circuit Components 3/3

- Carriage Mechanism / Ink System Mechanism 1/3

- Carriage Mechanism / Ink System Mechanism 2/3

- Carriage Mechanism / Ink System Mechanism 3/3

- Paper Feed Mechanism 1/8

- Paper Feed Mechanism 2/8

- Paper Feed Mechanism 3/8

- Paper Feed Mechanism 4/8

- Paper Feed Mechanism 5/8

- Paper Feed Mechanism 6/8

- Paper Feed Mechanism 7/8

- Paper Feed Mechanism 8/8

- Others 1/2

- Others 2/2

- Harness/FFC

- SC-P8500DL series/SC-T7700DL series

- Housing 1/5

- Housing 2/5

- Housing 3/5

- Housing 4/5

- Housing 5/5

- Electric Circuit Components 1/3

- Electric Circuit Components 2/3

- Electric Circuit Components 3/3

- Carriage Mechanism / Ink System Mechanism 1/3

- Carriage Mechanism / Ink System Mechanism 2/3

- Carriage Mechanism / Ink System Mechanism 3/3

- Paper Feed Mechanism 1/8

- Paper Feed Mechanism 2/8

- Paper Feed Mechanism 3/8

- Paper Feed Mechanism 4/8

- Paper Feed Mechanism 5/8

- Paper Feed Mechanism 6/8

- Paper Feed Mechanism 7/8

- Paper Feed Mechanism 8/8

- Others 1/2

- Others 2/2

- Harness/FFC

- RIPS Unit

- SC-P8500DM series/SC-T7700DM series/SC-T5700DM series

- Housing 1/4

- Housing 2/4

- Housing 3/4

- Housing 4/4

- Electric Circuit Components 1/3

- Electric Circuit Components 2/3

- Electric Circuit Components 3/3

- Carriage Mechanism / Ink System Mechanism 1/3

- Carriage Mechanism / Ink System Mechanism 2/3

- Carriage Mechanism / Ink System Mechanism 3/3

- Paper Feed Mechanism 1/8

- Paper Feed Mechanism 2/8

- Paper Feed Mechanism 3/8

- Paper Feed Mechanism 4/8

- Paper Feed Mechanism 5/8

- Paper Feed Mechanism 6/8

- Paper Feed Mechanism 7/8

- Paper Feed Mechanism 8/8

- Others 1/2

- Others 2/2

- Harness/FFC

- Scanner Unit 1/5

- Scanner Unit 2/5

- Scanner Unit 3/5

- Scanner Unit 4/5

- Scanner Unit 5/5

- SC-P8500D series/SC-T7700D series/SC-T5700D series/SC-P6500D series/SC-P6500DE series/SC-T3700D series/SC-T3700DE series/SC-P6500E series/SC-T3700E series

- Parts Layout Diagrams

- Operations Before/After Parts Exchange

- Disassembly and Assembly Procedure

- Preparation Before Starting Servicing

- Housing

- Home Side Cover Unit

- Full Side Cover Unit

- Front Top Cover

- Printer Cover Unit

- Take-up Button Board Cover

- Roll Removal Board Cover

- Maintenance cover

- Ink cartridge cover

- Ink Holder Housing

- Inner Home Side Lower Cover

- Inner Home Side Upper Cover

- Inner Full Side Cover

- Cutter Maintenance Cover

- Housing Support Plate

- Grounding Plate

- Paper Basket Unit

- Front Paper Guide Left

- Front Paper Guide Middle

- Front Paper Guide Right

- Paper Basket Stopper

- Platen Suction Fan.

- Home Side Top Cover

- Panel Hinge Cover

- Printer Cover Right Unit

- Panel Lower Cover

- Full Side Frame Cover

- Head Maintenance Cover Front

- Head Maintenance Cover Front Cover Sensor

- Head Maintenance Cover Rear

- Head Maintenance Cover Rear Cover Sensor

- Housing Rear Home Middle Cover

- Housing Rear Upper 1

- Housing Rear Upper 2

- Housing Rear Upper 3

- Housing Rear Upper 4

- Housing Rear Lower 1

- Housing Rear Lower 2

- Housing Rear Lower 3

- Housing Rear Full Middle Cover

- Housing Rear Lower 4

- Rear cover

- Housing Rear Lower 5

- Home Side Cover B

- Home Side Cover C

- Home Side Cover A

- Home Side Cover D

- Home Side Cover E

- Full Side Cover A

- Full Side Cover B

- Full Side Cover C

- Full Side Cover D

- Full Side Cover E

- Full Side Cover F/Full Side Cover G

- Port cover

- Lower Spindle Holder Cover H

- Lower Spindle Holder Cover D

- Lower Spindle Holder Cover E

- Lower Spindle Holder Cover F

- Lower Spindle Holder Cover G

- Lower Spindle Holder Cover A

- Lower Spindle Holder Cover B

- Lower Spindle Holder Cover C

- Front Cover

- Rear cover

- Left Cover

- Right Cover

- Electric Circuit Components

- Panel Assy

- Wireless LAN (WLAN) Board

- CH83 Sub IF Board

- CE46 SUB-C Board

- Option Slot Unit

- TPM (CH35 SUB T) Board

- Printer Main Circuit Board

- CH12Power Supply Board

- Head Maintenance LED (CF84 SUB-L) Board

- CH83 Main-B Circuit Board

- CH83 Main-B Circuit Board Unit

- CH83 DRV-H Board Cooling Fan

- CE46 SUB-R Board Home

- CE46 SUB-R Board Full Assy.

- CH83 SUB (PW/IMS) Board

- Inlet

- Take-up Button (CH83 SUB-S) Board

- Roll Removal Button (CH83 SUB-S) Board

- PSL Cooling Fan Unit

- CH83 DRV-H Board

- Panel FFC Assy

- Carriage Mechanism/Ink System Mechanism

- Temporary Removing of the Self Sealing Valve Assy

- CR Cover

- Self Sealing Valve Assy

- Print Head

- Tube Guide Plate

- Ink Tube Assy

- Front Upper Cover Sensor

- APG Unit

- Ink Cartridge Holder

- Ink Bifurcated Flow Channel Unit

- Ink Storing Box with Ink Leak Detection Sensor

- Maintenance Box Unit

- Cap Unit

- Pump Cap unit

- Wiper Cleaner

- Head FFC Assy

- CR Encoder

- CR Unit

- CR Scale

- CR Motor

- CR Slider (Home)

- CR Slider (Full)

- Head FFC Connector Clamp

- Tube Fixing Holder

- Paper Feed Mechanism

- ASF Motor Unit

- ASF Motor

- Sub PF Driven Sensor

- PF Release Sensor

- 1st Roll Paper Edge Detection Sensor

- 2nd Roll Paper Edge Detection Sensor

- 1st Paper Feed Driven Release Sensor/1st Paper Path Paper Detection Sensor

- 2nd Paper Feed Driven Release Sensor/2nd Paper Path Paper Detection Sensor

- Paper Eject Driven Roller Belt

- PF Scale

- PF Driven Roller Motor

- Sub PF Scale

- Sub PF Driven Roller Motor

- PF Encoder

- PF Scale Encoder Unit

- Sub PF Encoder

- Sub PF Scale Encoder Unit

- PF Belt

- Sub PF Belt

- BPE Sensor

- UPE Sensor

- 1st Roll Paper Motor

- 2nd Roll Motor

- 1st Roll Paper Motor Assy / 1st Roll Paper Gears

- 2nd Roll Paper Motor Assy / 2nd Roll Paper Gears

- Paper Eject Star Wheel Roller Motor Unit

- 1st/2nd Release Motor

- 1st Roll Spindle Lock Position Detection Sensor Full

- 2nd Roll Spindle Detection Sensor

- 2nd Roll Spindle Lock Position Detection Sensor

- 1st Roll Spindle Lock Position Detection Sensor Home

- 1st Roll Spindle Detection Sensor

- Rear Cover Sensor

- PF Roller Middle Support (Full)

- PF Roller Middle Support (Home)

- Paper Guide Position Detection Sensor Upper

- Paper Guide Position Detection Sensor Lower

- ASF Gears

- Cutter Rail Unit

- Cutter Motor Unit

- Cutter Home Position Detect Sensor

- Full Side Paper Eject Release Roller Support

- Home Side Paper Eject Release Roller Support

- Paper Eject Driven Roller Shaft Unit

- Paper Eject Driven Roller Unit

- ASF sub Gears

- Home Side 1st Roll Paper Guide

- Home Side 2nd Roll Paper Guide

- Full Side 1st Roll Paper Guide

- Full Side 2nd Roll Paper Guide

- Home Side Upper Roll Paper Guide Parts

- Home Side Lower Roll Paper Guide Parts

- Paper Eject Release Roller Belt Cover

- Paper Guide Rear

- Temporary Removing of the Paper Guide Rear Home

- Paper Guide Rear Home

- Platen Paper Guide Rear

- Nip Release Roller/Nip Release Roller Holder

- Spring

- Production Stacker Paper Jam Detection Sensor

- Full Side Paper Support Shaft

- Home Side Paper Support Shaft

- Paper Support Unit

- Board Paper Guide Roller (Full)

- Board Paper Guide Roller (Middle)

- Board Paper Guide Roller (Home)

- Paper Thickness Sensor

- 1st Roll Paper Nip Roller Spring

- 2nd Roll Paper Nip Roller Spring

- Spindle Cover

- Other Parts

- Harness/FFC

- RIPS Unit

- Scanner

- Scanner Unit

- Scanner Main Board

- Scanner Sub Board

- CIS Module Home Side

- CIS Module Center

- CIS Module Full Side

- CIS Module Home Side Board

- CIS Module Center Board

- CIS Module Full Side Board

- White Base Assy Home Side

- White Base Assy Center

- White Base Assy Full Side

- Skew Sensor Home Side

- Document Feed Sensor

- Skew Sensor Full Side

- Document Feed Scale

- Document Feed Scale Encoder

- Document Feed Motor

- Top Scale

- PE Sensor (Scanner)

- Scanner Unit Open Sensor

- Scanner Paper Feed Flap Opening / Closing Sensor

- Paper Detect Sensor

- Left Lever Open Sensor

- Right Lever Open Sensor

- Scanner Paper Feed Flap Motor Assy

- Flap Gears

- Scanner Paper Feed Flap

- Document Feed Gears

- C Shape Washer/Fixing Slider (Scanner Hinge both side)

- Scanner Full Side Front Cover

- Scanner Home Side Cover

- Scanner Front Cover

- Scanner Front Top Cover

- Printer Top Cover

- Right Front Guide A Assy

- Right Front Guide B

- Right Front Guide C

- Right Rear Guide A

- Right Rear Guide B

- Right Edge Front Guide

- Right Edge Rear Guide

- Left Front Guide A

- Left Front Guide B

- Left Front Guide C

- Left Rear Guide A

- Left Rear Guide B

- Left Edge Front Guide

- Left Edge Rear Guide

- Center Front Guide A

- Center Front Guide B

- Center Front Guide C

- Center Rear Guide A

- Center Rear Guide B

- Modes & Tools for Service

- Adjustment & Additional Operations

- Adjustment & Additional Operations

- List of Tools/Software/Consumables for Adjustments

- Repair Parts Adjustment/Checks Items and Order

- Electric Circuit Board Related Parts

- Wireless LAN (WLAN) Board

- CH83 Sub IF Board

- CE46 SUB-C Board

- TPM (CH35 SUB T) Board

- Printer Main Circuit Board (With SSD/PS) (NVRAM backup OK)

- Printer Main Circuit Board (With SSD/PS) (NVRAM backup NG)

- Printer Main Circuit Board (Without SSD/PS) (NVRAM backup OK)

- Printer Main Circuit Board (Without SSD/PS) (NVRAM backup NG)

- CH12Power Supply Board

- CH83 Main-B Circuit Board

- CH83 DRV-H Board Cooling Fan

- CH83 SUB (PW/IMS) Board

- CH83 DRV-H Board

- CR/Head/Ink System related

- Pump Cap unit

- Cap Unit

- Print Head

- Self Sealing Valve Assy (common when using/not using pliers jig)

- Ink Bifurcated Flow Channel Unit (when not using pliers jig)

- Ink Bifurcated Flow Channel Unit (when using pliers jig)

- CR Motor

- Head FFC Assy

- CR Encoder

- CR Scale

- CR Unit

- Ink Cartridge Holder

- Maintenance Box Unit

- Ink Tube Assy (when not using pliers jig)

- Ink Tube Assy (when using pliers jig)

- Ink Storing Box with Ink Leak Detection Sensor

- Bk_CR Slider (Home)/CR Slider (Full)

- PF related

- Sub PF Driven Roller Motor

- BPE Sensor

- UPE Sensor

- PF Scale

- Sub PF Scale

- PF Encoder

- Sub PF Encoder

- Paper Basket Unit

- 1st Paper Feed Driven Release Sensor/1st Paper Path Paper Detection Sensor

- 2nd Paper Feed Driven Release Sensor/2nd Paper Path Paper Detection Sensor

- PF Roller Middle Support (Home)/PF Roller Middle Support (Full)

- PF Release Sensor

- Sub PF Driven Sensor

- 1st Roll Paper Edge Detection Sensor

- 2nd Roll Paper Edge Detection Sensor

- 1st Roll Paper Motor

- 2nd Roll Motor

- ASF Motor Unit

- 1st/2nd Release Motor

- Paper Eject Driven Roller Belt

- PF Timing Belt

- Sub PF Timing Belt

- Cutter Motor Unit

- Cutter Rail Unit

- Cutter Home Position Detect Sensor

- Platen Suction Fan.

- Paper Eject Star Wheel Roller Motor Unit

- 1st Roll Spindle Detection Sensor

- 2nd Roll Spindle Detection Sensor

- 1st Roll Spindle Lock Position Detection Sensor Home

- 2nd Roll Spindle Lock Position Detection Sensor

- Rear Cover Sensor

- Paper Guide Position Detection Sensor Upper

- Paper Guide Position Detection Sensor Lower

- Production Stacker Paper Jam Detection Sensor

- Others_1

- RIPS Unit

- Scanner Unit

- CIS Module Center

- CIS Module Full Side

- White Base Assy Home Side

- White Base Assy Center

- White Base Assy Full Side

- Skew Sensor Home Side

- Skew Sensor Full Side

- Document Feed Sensor

- Document Feed Motor

- Document Feed Scale

- Document Feed Scale Encoder

- Document Feed Gears

- Scanner Unit

- Scanner Main Board (Backup OK)

- Scanner Main Board (Backup NG)

- Scanner Paper Feed Flap Opening / Closing Sensor

- Scanner Paper Feed Flap

- Scanner Paper Slot Motor

- Flap Gears

- Electric Circuit Board Related Parts

- Adjustments and Check Items Purpose

- Boards Related Adjustments

- NVRAM Data Backup & Restore

- Write Setting Value Information

- Write NW/Authentication Data

- Firmware Install

- Main Circuit Board Initial Setting

- Input Offset Value

- RTC Check & Input

- MAC Address Check & Input

- Serial Number Input

- Option SSD/PS3 Unit S/N information Write to NVRAM

- Main Circuit Board Replacement Date & Time Setting

- Power Supply Board Replacement Date & Time Setting

- DRV-H Board Replacement Date & Time Setting

- Main-B Board Replacement Date & Time Setting

- TPM (CH35 SUB T) Board Replacement Date & Time Setting

- CR/Head Related Adjustments

- Move the Print Head to Replacement Position

- Head Grounding Resistance Check

- Head ID Check & Input

- CR Belt Deflection Adjustment

- CR Belt Tension Check & Adjustment

- CR Scale Check

- CR Motor Measurement & Auto Adjustment

- Head Alignment Check

- Nozzle Verification Technology Noise Check

- Nozzle Verification Technology Rank Sort (including initialization)

- Nozzle Verification Technology Check

- Nozzle Verification Technology Trouble Check

- PG Check & Adjustment

- IMS Adjustment

- Head Inclination Check & Adjustment (CR direction)

- Head Slant Check & Adjustment (PF direction)

- Uni-D Alignment

- Bi-D Adjustment

- Ruled Line Deviation Adjustment (Auto)

- Ruled Line Deviation Adjustment (Manual)

- Colorimetric & Raster Calibration

- Ink Supply Related Adjustments

- Unlock the Wiper from Wiper Cleaner

- Pump Cap Unit Measurement & Auto Adjustment

- Cleaning

- Initial Ink Charge

- Ink Leak Flag Reset

- Ink Tube Inner Pressure Reduction

- The Supply Tube Ink Filling

- Head / Self-Sealing Valve Ink Filling

- Ink Discharge

- Tube Wash

- Initial Ink Charge Flag On / Off

- Ink Bifurcated Flow Channel Unit Replacement Date & Time Setting

- Ink Holder (RIPS) Replacement Ink Filling

- Media Feed Related Adjustments

- Release the PF Driven Roller

- PF Belt Tension Check & Adjustment

- Sub PF Belt Tension Check & Adjustment

- PF Motor Measurement & Auto Adjustment

- Sub PF Motor Measurement & Auto Adjustment

- Cutter Motor Measurement & Auto Adjustment

- Cutter Motor Life Span Measurement & Auto Adjustment

- 1st / 2nd Release Motor Measurement & Adjustment

- 1st Roll Paper Motor Measurement & Adjustment

- 2nd Roll Paper Motor Measurement & Adjustment

- Paper Feed Adjustment

- Cut Position Check & Adjustment

- PW Sensor Check & Adjustment

- T&B&S Check & Adjustment

- PF Scale Check

- Sub PF Scale Check

- Suction Fan Input & Check

- Rear AD Adjustment (UPE)

- Rear AD Adjustment (BPE)

- Paper Eject Star Wheel Roller Motor Unit & Sensor Working Check

- Paper Eject Release Roller Belt Tension Check & Adjustment

- Shutter Motor Working Check

- Counter Reset

- Pump Cap Counter Reset

- Ink Cartridge Holder Counter Reset

- Ink Tube Counter Reset

- Print Head Counter Reset

- Self Sealing Valve Counter Reset

- PF Driven Roller Motor Counter Reset

- Sub PF Driven Roller Motor Counter Reset

- CR Motor Counter Reset

- Cutter Motor Counter Reset

- ASF Motor Unit Counter Reset

- 1st/2nd Release Motor Counter Reset

- 1st Roll Paper Motor Counter Reset

- 2nd Roll Paper Motor Counter Reset

- Paper Eject Star Wheel Roller Motor Unit Counter Reset

- Shutter Motor Unit Counter Reset

- APG Unit Counter Reset

- PF Roller Middle Support (Home/Full) Counter Reset

- Ink Pans Counter Reset

- Pump Unit Counter Reset

- CIS Module Home Side Counter Reset

- CIS Module Center Counter Reset

- CIS Module Full Side Counter Reset

- Document Feed Motor Counter Reset

- Other Printer Adjustments

- Scanner Related Adjustments

- Document Feed Motor Measurement

- Document Feed Sensor & Skew Sensor Adjustment

- Shading Calibration (Basic Adjustment)

- CIS Modules Position & Document Feed Adjustment

- Scanner Main Board Replacement Date & Time

- Scanner Unit Replacement Date & Time Setting

- Scanner Paper Feed Flap Opening / Closing Sensor Check

- Maintenance

- Maintenance & Inspection

- Appendix