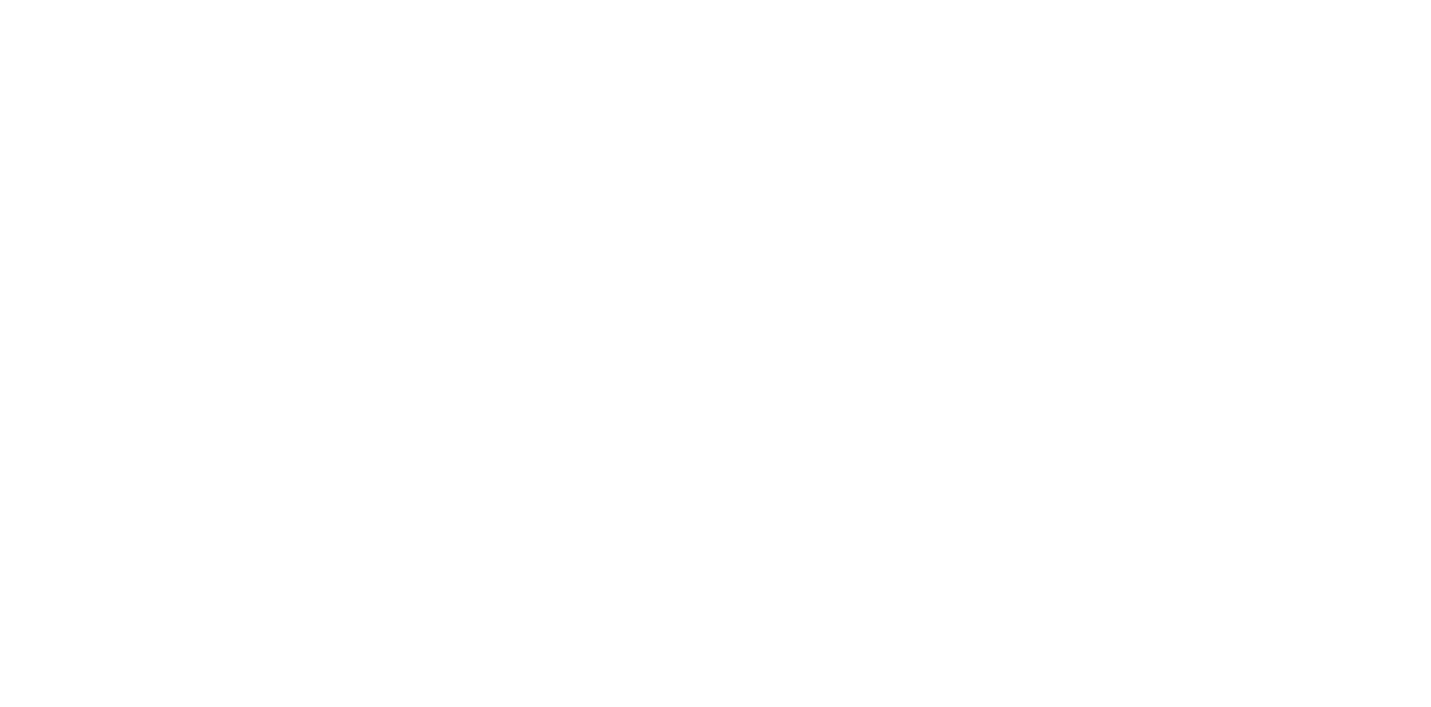

Sensor Position

Front Side (1st Roll)

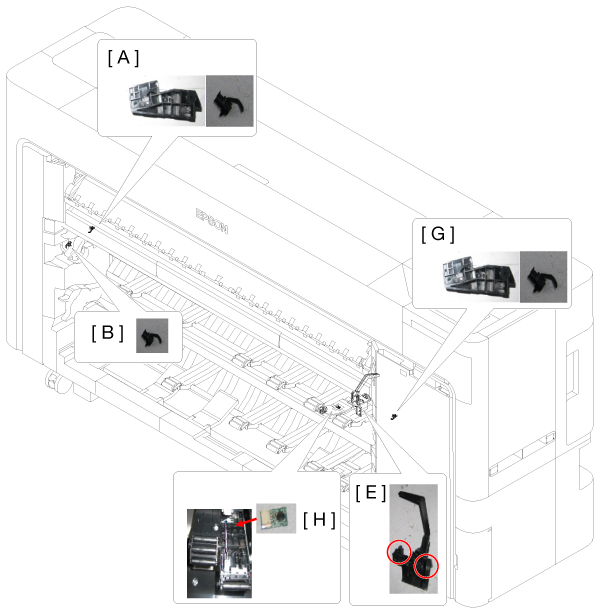

Front Side (2nd Roll)

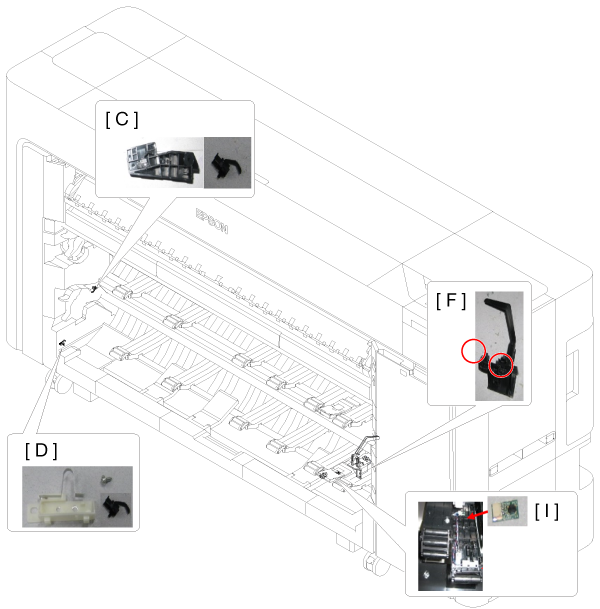

Rear Side

| No. | Sensor name | Role | When use | Error / malfunction phenomenon that occurs when the sensor | Type | When saving power |

|---|---|---|---|---|---|---|

| A | 1st Roll Spindle Lock Position Detection Sensor Full | Check if there is the 1st roll spindle lock or not. | Paper feeding with 1st roll paper (moves without a spindle). Confirmed at the time of paper feeding to ensure that the spindle is locked. |

| Mechanical switch | ON |

| B | 1st Roll Spindle Detection Sensor | Check if there is the 1st roll spindle or not. |

| Mechanical switch | ON | |

| C | 2nd Roll Spindle Lock Position Detection Sensor | Check if there is the 2nd roll spindle lock or not. | Feeding with 2nd roll paper (moves without a spindle). Confirmed at the time of paper feeding to ensure that the spindle is locked. |

| Mechanical switch | ON |

| D | 2nd Roll Spindle Detection Sensor | Check if there is the 2nd roll spindle or not. |

| Mechanical switch | ON | |

| E | 1st Roll Paper Detection Sensor Unit

|

| When feeding, printing, and ejecting the paper (when used as a roll paper or winder) |

| Through beam | OFF |

| F | 2nd Roll Paper Detection Sensor Unit

|

| When feeding, printing, and ejecting the paper (roll paper only) |

| Through beam | OFF |

| G | 1st Roll Spindle Lock Position Detection Sensor Home | Check if there is the 1st roll spindle lock or not. | Paper feeding with 1st roll paper (moves without a spindle). Confirmed at the time of paper feeding to ensure that the spindle is locked. |

| Mechanical switch | ON |

| H | 1st Roll Paper Edge Detection Sensor | Look at the tip of the paper: it may not be readable if it is a mess of paper → Not used for manual paper feeding (roll paper, but tracing paper (media that easily sticks or does not come off, film media) | When feeding the paper |

| Reflective | OFF |

| I | 2nd Roll Paper Edge Detection Sensor | Look at the tip of the paper: it may not be readable if it is a mess of paper → Not used for manual paper feeding (roll paper, but tracing paper (media that easily sticks or does not come off, film media) | When feeding the paper |

| Reflective | OFF |

| J | UPE Sensor |

| When feeding, printing, or ejecting board paper / cut sheet paper. |

| Reflective | OFF |

| K | BPE Sensor |

| When feeding roll paper, printing (including roll end detection), and ejecting paper. |

| Reflective | OFF |

| L | Rear Cover Sensor | Confirmation of opening and closing of the back cover | When paper jam occurs. |

| Mechanical switch | OFF |

| M | Paper Thickness Sensor |

| When feeding board paper / non-board paper |

| Through beam | OFF |

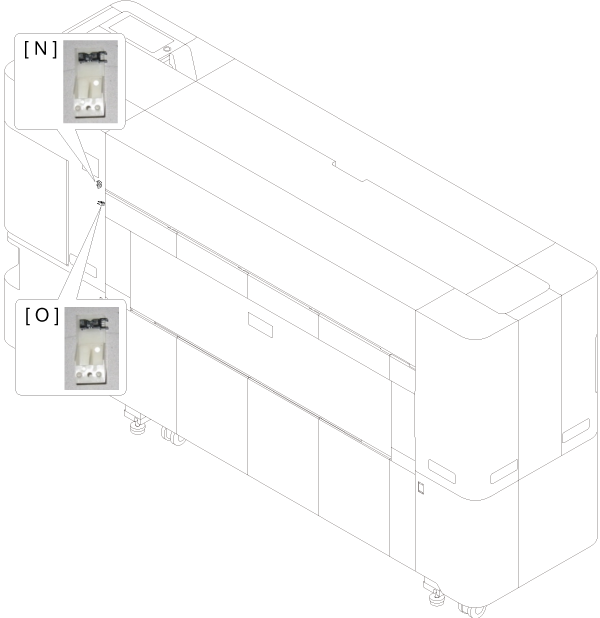

Rear Side

Front Side

| No. | Sensor name | Role | When use | Error code that occurs when the sensor fails(or being broken) | Error / malfunction phenomenon that occurs when the sensor | Type | When saving power |

|---|---|---|---|---|---|---|---|

| N | PF Release Sensor (PF Driven RLS Sensor) | Check if the PF driven roller is Nip | When feeding paper, when discharging paper. |

| Through beam | OFF | |

| O | Sub PF Release Sensor (Middle Driven RLS Sensor) | Check if the Sub PF driven roller is Nip | When feeding paper, when discharging paper. | Through beam | OFF | ||

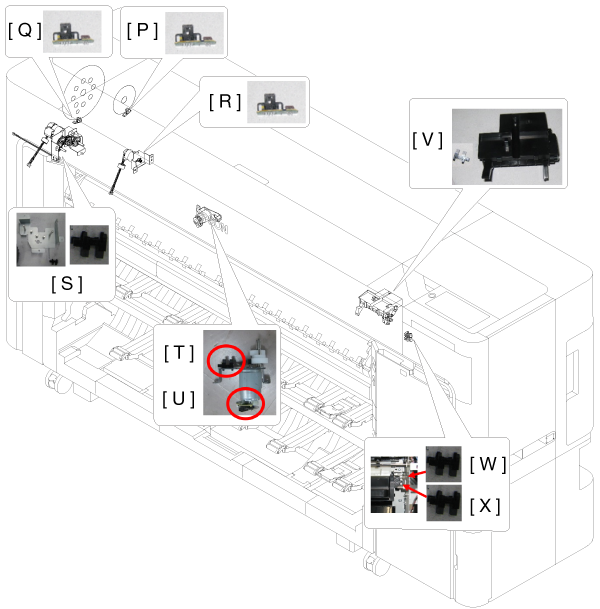

| P | Sub PF Encoder | The scale of the sub PF roller is read and the position is confirmed. | When the power is ON, when feeding, and discharging paper. | Through beam | OFF | ||

| Q | PF Encoder | The scale of the sub PF roller is read and the position is confirmed. | When the power is ON, when feeding, and discharging paper. | Through beam | OFF | ||

| R | 1st / 2nd Release Motor |

| If being not at the origin when the power is turned on, look for it (PF driven sensor) (PF driven RLS sensor) Sub PF driven sensor. (It does not move if it recognizes that it is at the origin with an intermediate driven RLS sensor), when feeding paper, when printing. |

| Through beam | OFF | |

| S | Paper Eject Star Wheel Roller Motor Unit Release encoder |

| Most of them are used at the time of printing except for film type (media whose surface is easily scratched: photo glossy paper is used). |

| Through beam | OFF | |

| Paper Eject Star Wheel Roller Motor Unit Release sensor | Floating jagged / EJ drive jagged Nip / Release position confirmation sensor | Through beam | OFF | ||||

| T | Shutter Motor Unit (Negative pressure chamber switching partition plate RLS sensor) | Checking the opening and closing of the negative pressure chamber of the negative pressure chamber switching partition plate. | When printing (reading the width of the paper (reading with the PW sensor), it opens and closes. Closes the negative pressure chamber for 30 inches or less) | Through beam | OFF | ||

| U | Shutter Motor Unit (Negative pressure chamber switching encoder) |

| Through beam | OFF | |||

| V | Production Stacker Paper Jam Detection Sensor (Stacker Paper Jam Detection) | Sensor to check if paper jam has occurred in the print stacker. | When using the print stacker and when printing | --- |

| Through beam |

|

| W | Paper Guide Position Detection Sensor Upper | Sensor for detecting the position of the paper support lock lever |

| --- | Lock lever position incorrect error | Through beam | OFF |

| X | Paper Guide Position Detection Sensor Lower | --- | Through beam | OFF | |||