Confirmation After The Repair

The following lists the recommended items to be checked after the repair work.

Purpose: To ensure the quality of repair

| Check Item | Check |

|---|

- Was the customer’s problem solved?

| □ |

- Were there any problems that occurred other than those reported by the customer?

- If any such problems occurred, were they solved as well?

| □ |

- Confirm that the counter values for the life parts are not close to the end of their lives. (Repair suggestions to customers)

If any parts have reached 90% of their life, make suggestions to the customer regarding replacement, etc.

- <Checking method>:

Use the NVRAM Viewer tool to check the ratio to the end of life based on the data backed up with “Backup Parameters” or “NVRAM Data Backup” and acquired from the service program.

| □ |

- Did you check the error history to see if there are any problems other than those to be addressed in the repair work?

| □ |

- Are all the printed nozzle check patterns and head alignment patterns clearly printed out?

| □ |

- Did you check and report the condition of the repaired printer?

| □ |

- Confirm if there are any complaints from the customer after printing the print pattern concerned on the repaired printer.

| □ |

- Ask the customer to check with the print patterns and medias concerned to confirm that the problem was solved.

| □ |

- If the above actions do not resolve the problem, please report it to the person in charge.

- <Items to be reported>:

- Backed-up NVRAM data

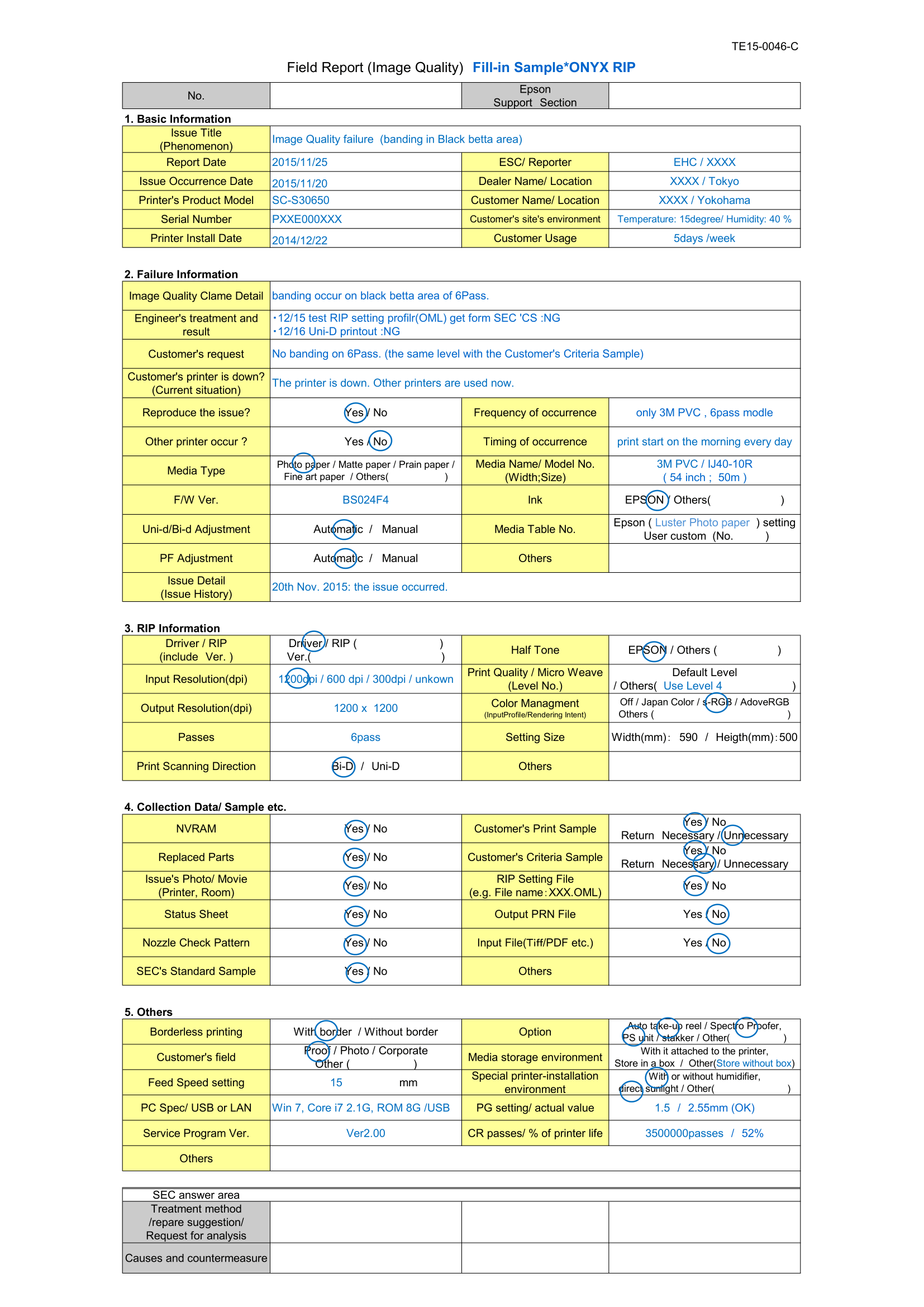

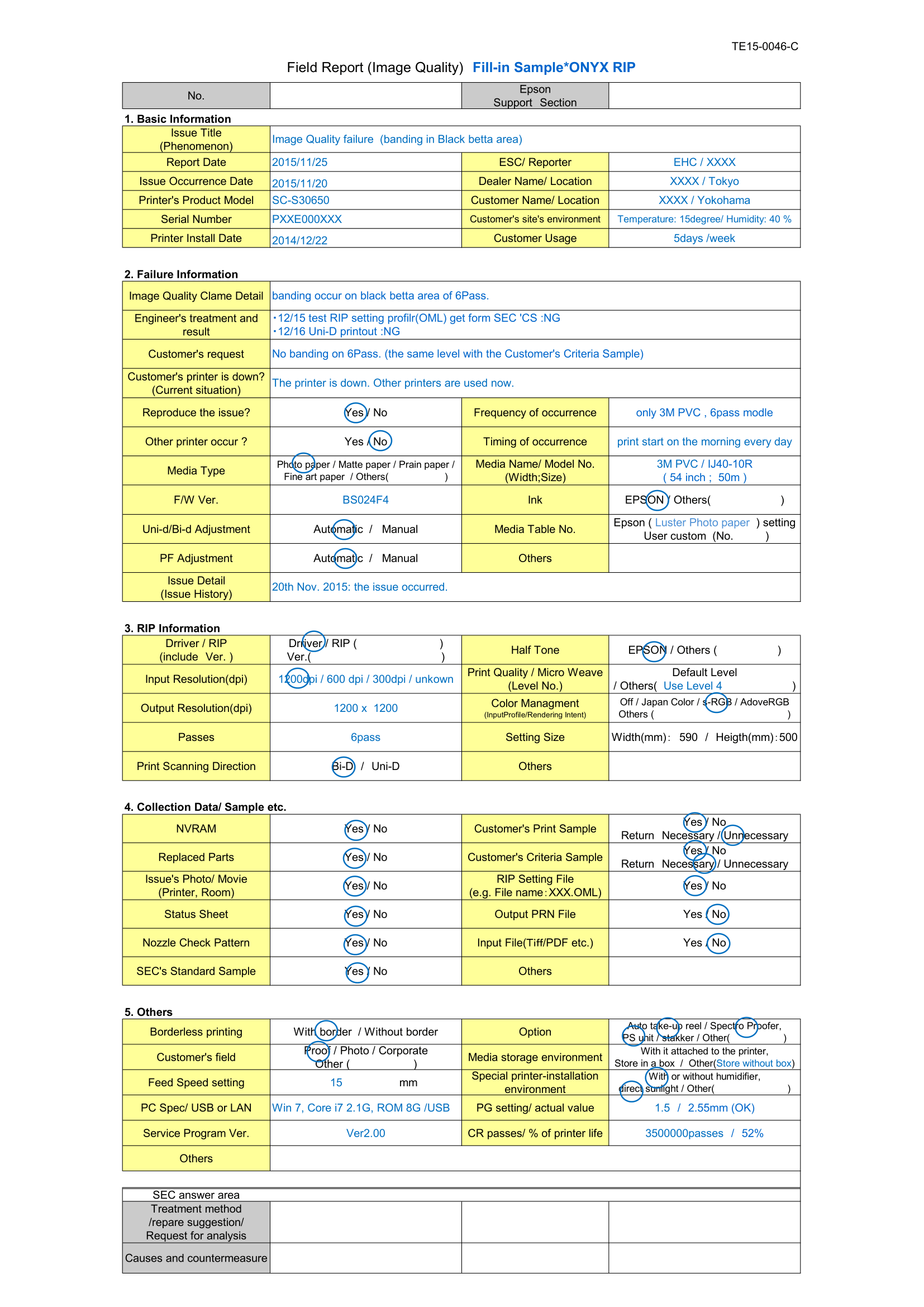

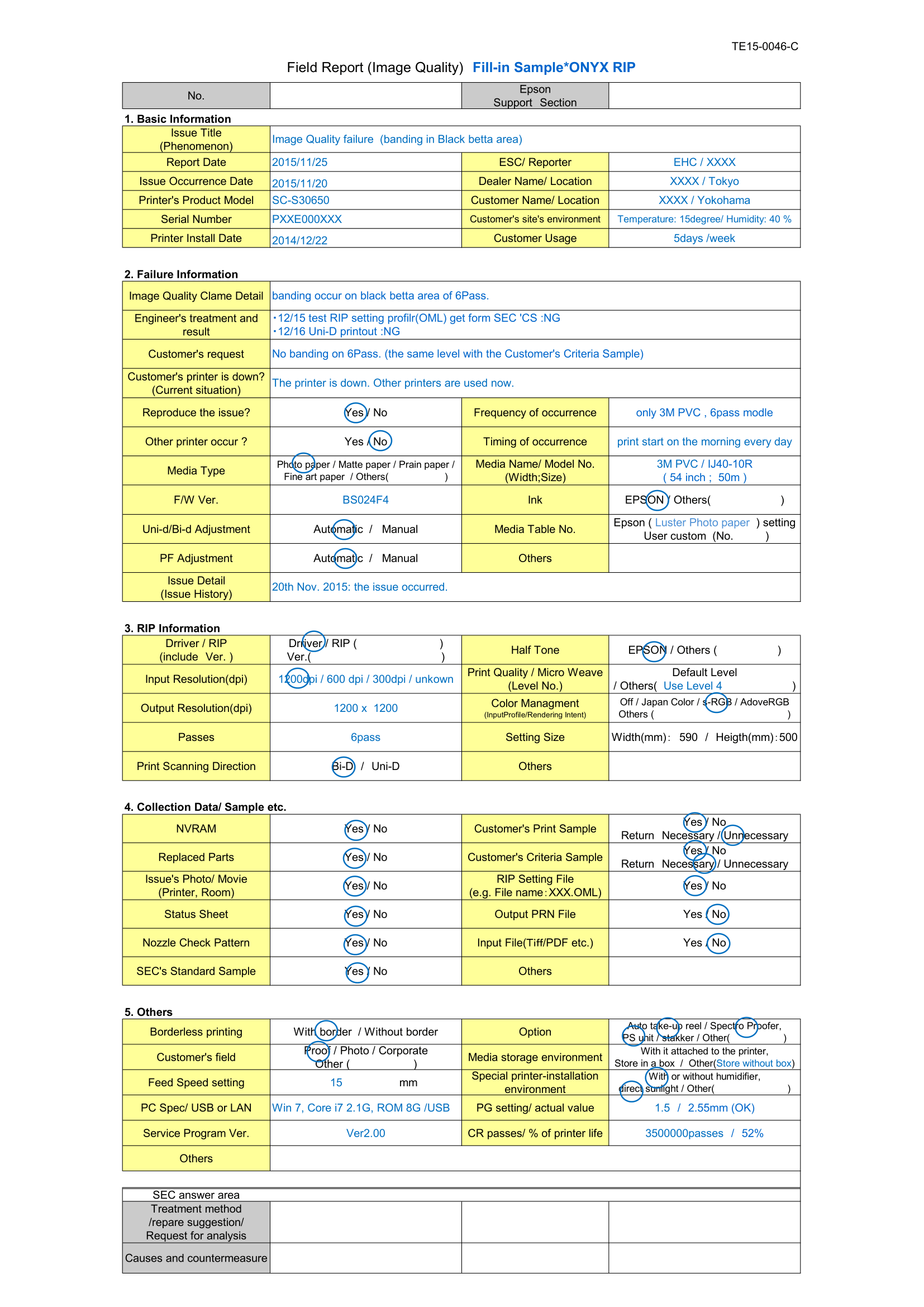

- Fill in the information collection format with the relevant information and then report it.

Ex.): Refer to JP: TI No.”TJ15-0552” and send us a feedback.

|

|