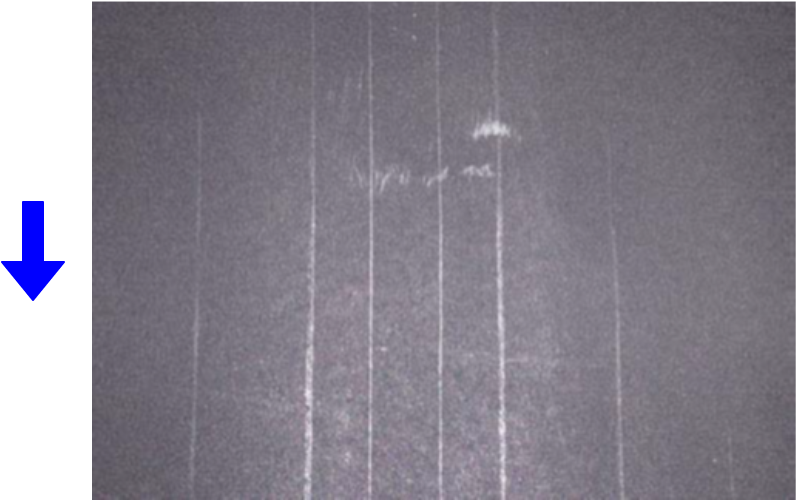

Damage on printed surfaces (2)

Paper is fed from the direction of the arrow.)

Suspected cause

- High ink density during printing.

- The shape of the Paper Eject Star Wheel Roller Unit is old.

Parts/Components to be checked

- Paper settings on the main unit panel

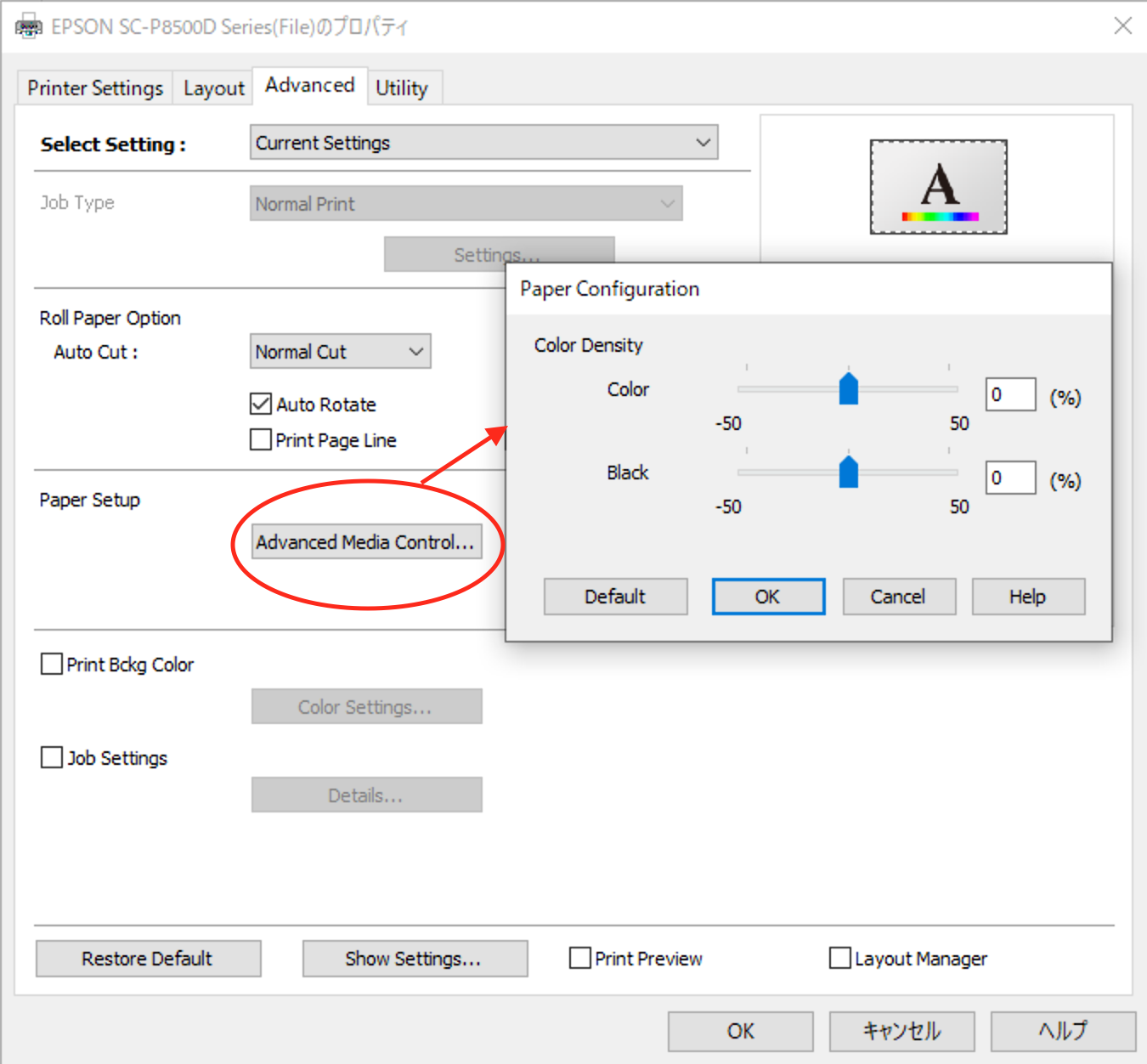

- Paper adjustment on the printer driver

- Paper Eject Driven Roller Unit

Troubleshooting

| Step | Confirmation points and methods | Page | YES | NO |

|---|---|---|---|---|

| 1 | Set not to use the paper ejection roller

Does the product recover from the failure? | --- | End | Go to step 2 |

| 2 | Reduce the printing ink concentration

Does the product recover from the failure? | --- | End | Go to step 3 |

| 3 | Replace the Paper Eject Star Wheel Roller Unit Does the product recover from the failure? | Paper Eject Driven Roller Unit | End | Escalate to person in charge |