Paper Feed Flow

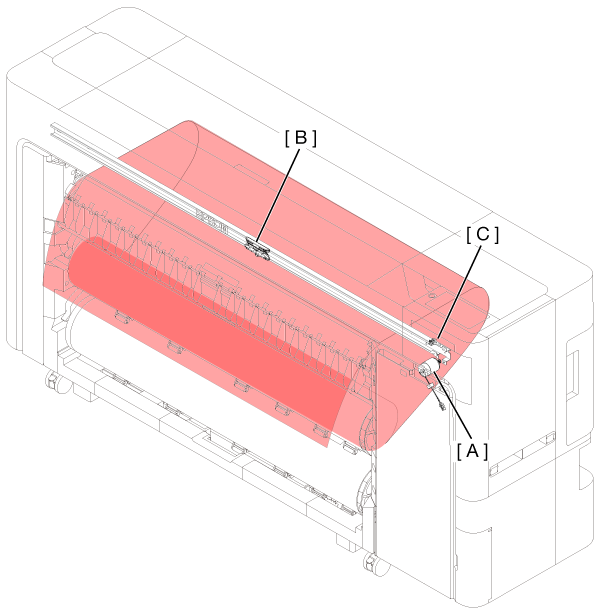

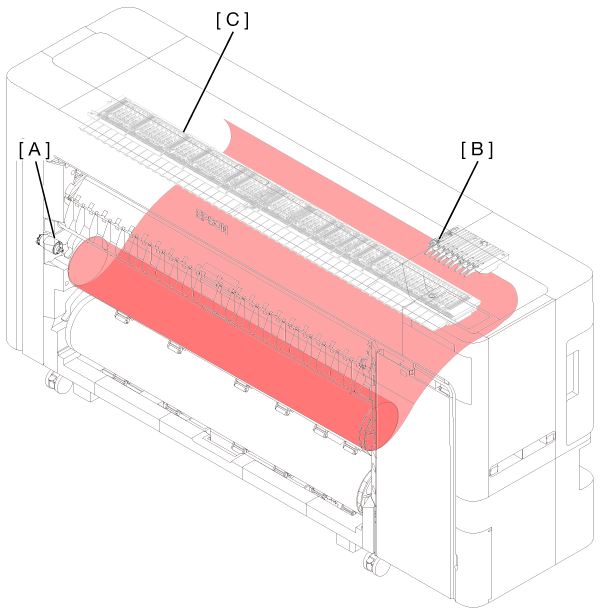

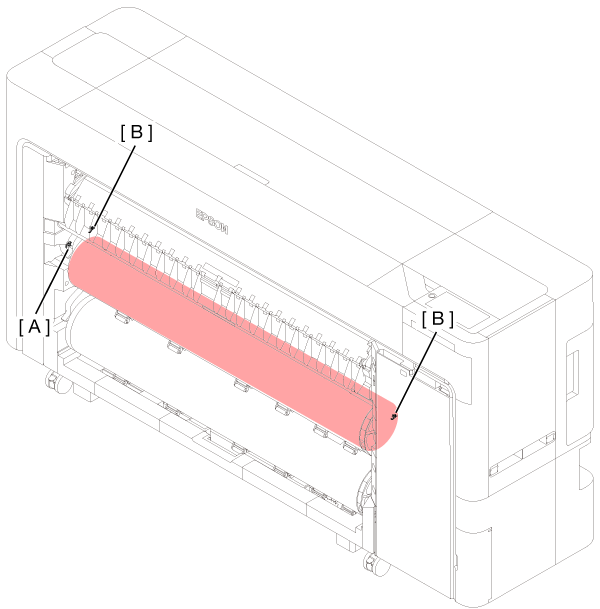

Check the spindle

- Detect the spindle position by 1st Roll Spindle Detection Sensor (A).

- Detect these spindles are locked by 1st Roll Spindle Lock Position Detection Sensor Full/Home (B).

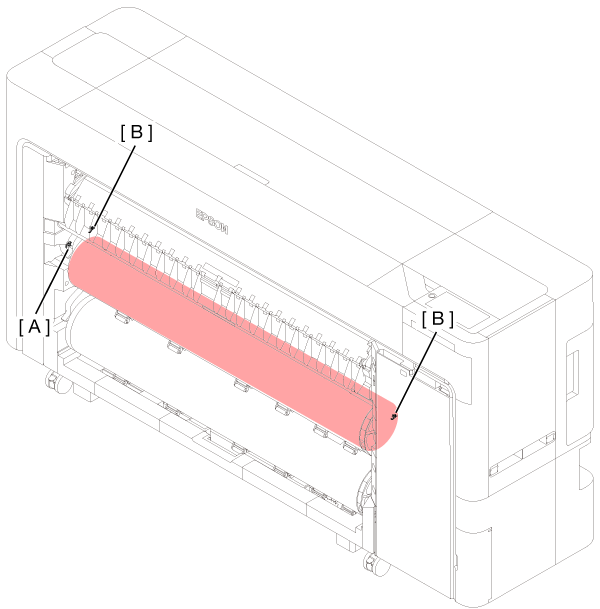

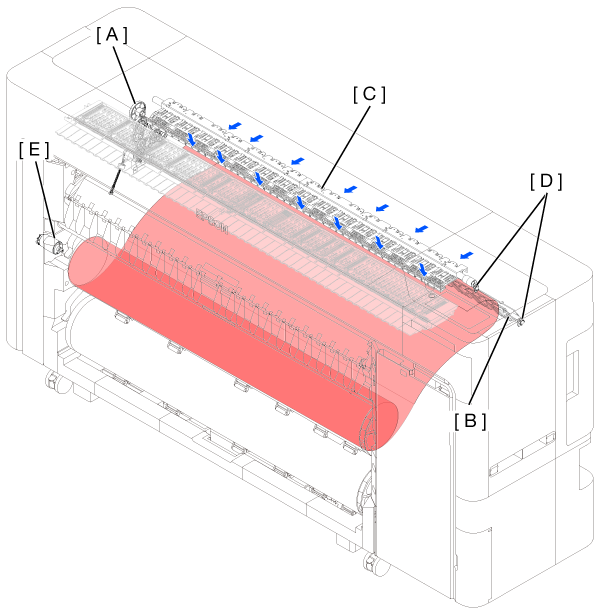

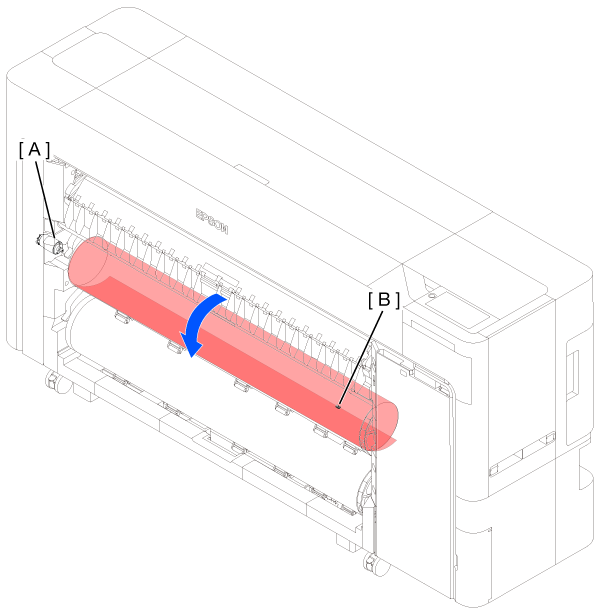

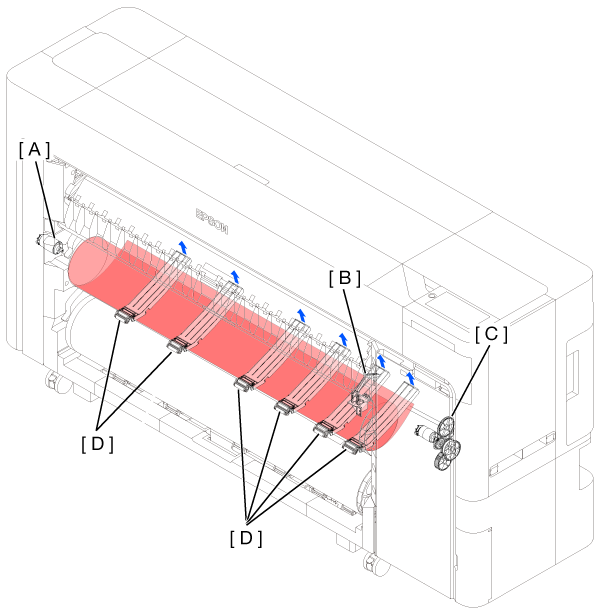

Roll paper feeding

- Rotate the roll paper by 1st Roll Paper Motor Assy (A).

- Detect the paper edge by 1st Roll Paper Edge Detection Sensor (B).

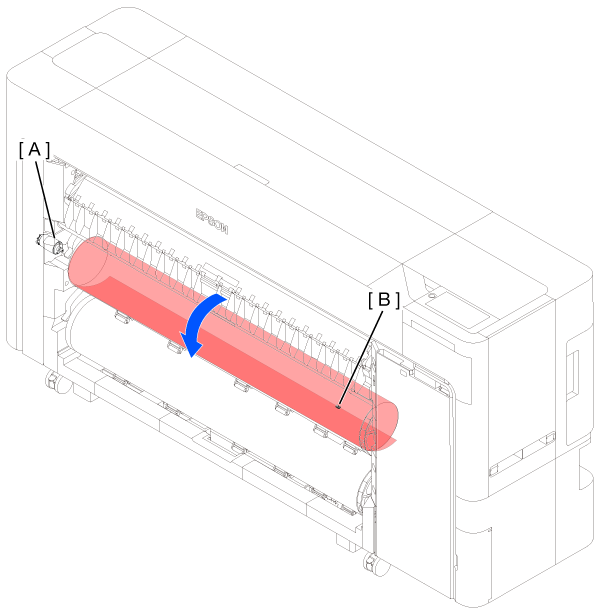

- Rotate and load the paper to inside printer by 1st Roll Paper Motor Assy (A).

- Detect the media by 1st Roll Paper Detection Sensor Unit (B).

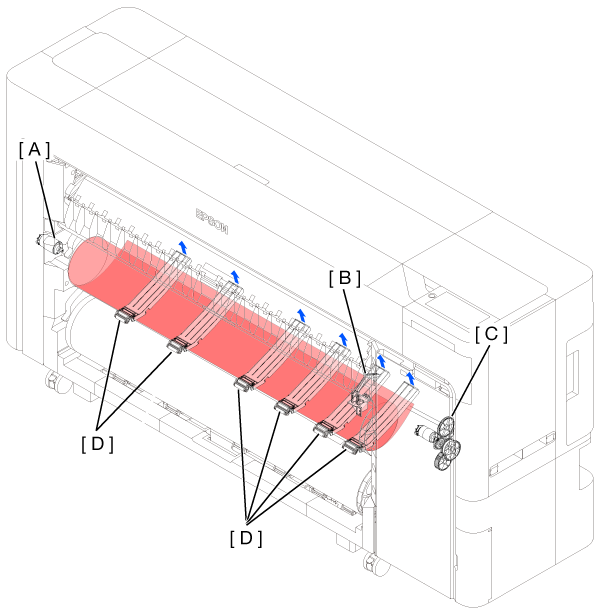

- Operate ASF motor and ASF gears (C) and nip the media by the 1st roll arm (D).

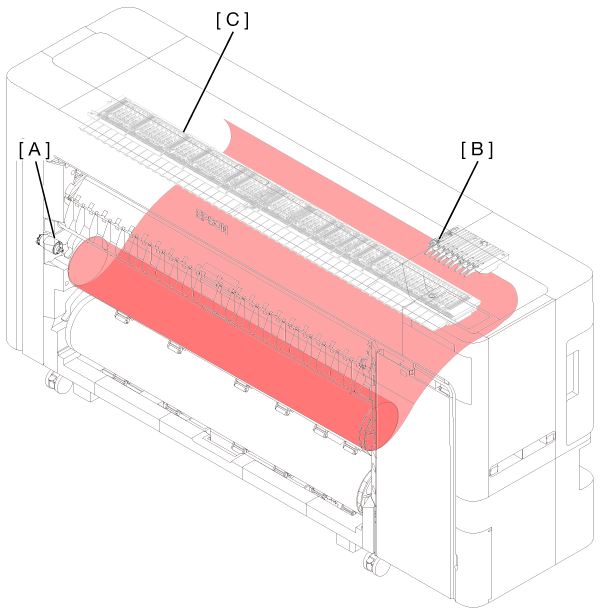

- Rotate and load the paper to inside printer by 1st Roll Paper Motor Assy (A).

- Detect the media with the BPE sensor (B) and send the media to the platen (C).

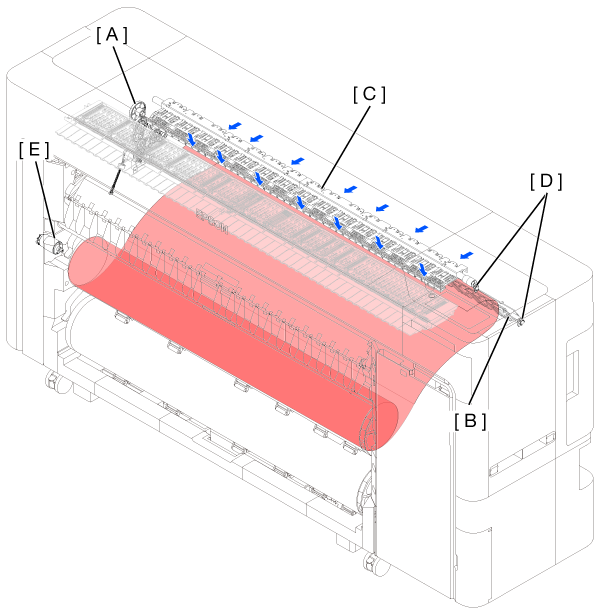

- Operate the 1st / 2nd Release Motor/ASF sub Gears (A) and nip the PF driven roller (B) and Sub PF driven roller (C).

- Check the nip status by PF Release Sensor / Sub PF Release Sensor (D).

- Feed the media to printer platen by rotating 1st Roll Paper Motor Assy (E).

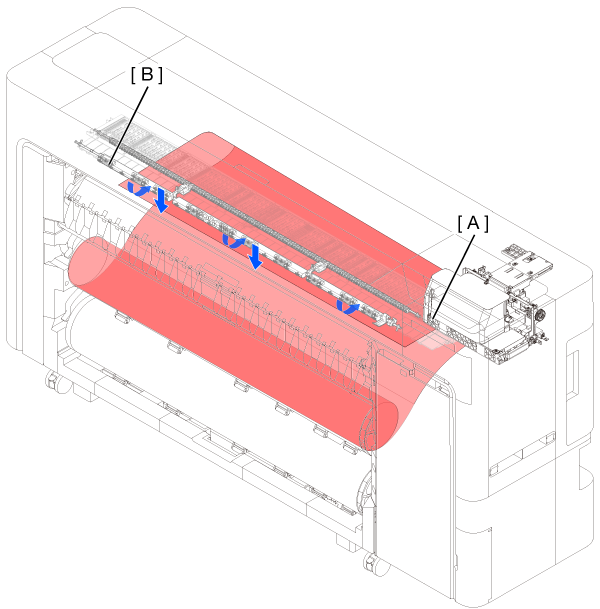

- Detect the media by CR unit PW sensor (A) and set the media to standby position (Depending on the media type, the media is nip by Paper Eject Star Wheel Roller Unit (B)).

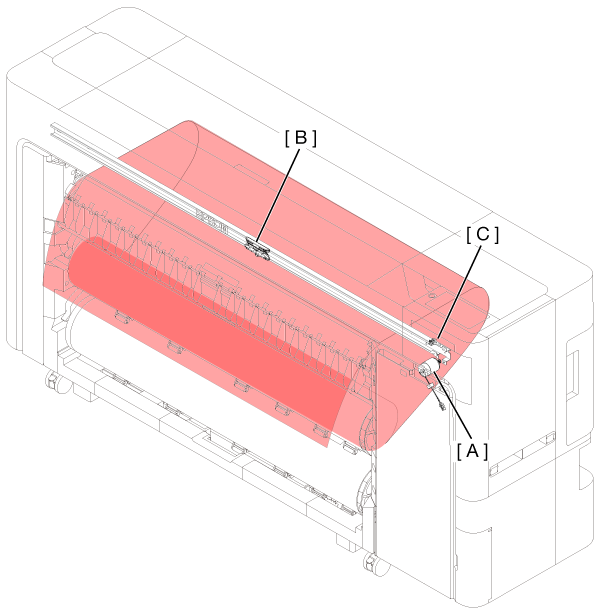

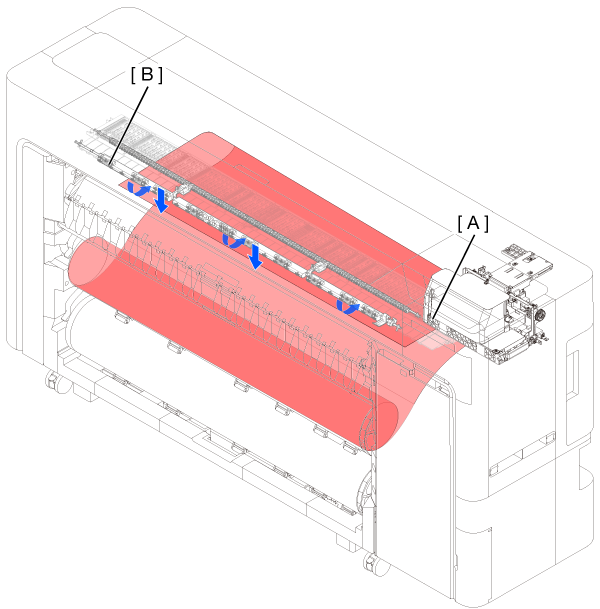

After printing roll paper

- After printing, Cutter motor unit (A) moves Cutter (B) from Home side to Full side to cut the printed media.

- Detect the cutter return to home position by Cutter Home Position Detect Sensor (C).