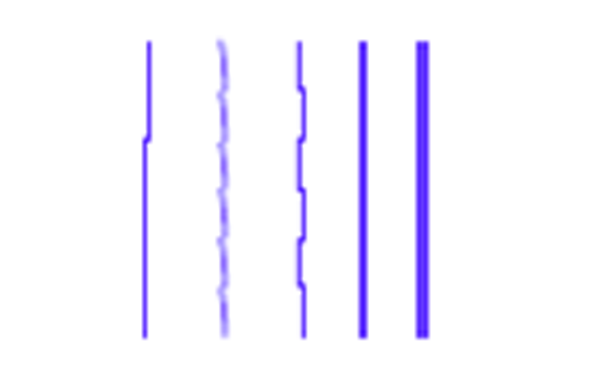

Horizontal or vertical lines look misaligned, become a double line, or become thick.

Suspected cause

Bi-D Adjustment failure

Print Head related adjustment failure (inclination, slant/ruled line deviation adjustment)

PG adjustment failure

Wiping cannot be performed properly due to a contaminated wiper, wiper failure or contaminated wiper cleaner.

If this only occurs at the start of printing, this could be because of thickened ink.

Parts/Components to be checked

Print Head (ink thickening on nozzle surface)

Pump Cap unit

Wiper Unit

Wiper Cleaner

Problem with seal part of the Cap Unit

Ink dripping within cap, causing thickening

Ink Cartridge (is old)

Troubleshooting

| Step | Confirmation points and methods | Page | YES | NO |

|---|---|---|---|---|

| 1 | Perform Bi-D Adjustment Does the product recover from the failure? | Bi-D Adjustment | End | Go to step 2 |

| 2 | Perform head Inclination adjustment (CR direction)/head slant adjustment (PF direction)/Ruled line deviation adjustment Does the product recover from the failure? | Head Inclination Check & Adjustment (CR direction) | End | Go to step 3 |

| 3 | Perform PG Check & Adjustment Does the product recover from the failure? | PG Check & Adjustment | End | Go to step 4 |

| 4 | Check and clean dirt off the wiper. Alternatively, if ink has hardened and dirt cannot be removed, replace the wiper. Does the product recover from the failure? | Wiping around the Cap | End | Go to step 5 |

| 5 | Replace the Wiper Cleaner Does the product recover from the failure? | Wiper Cleaner | End | Go to step 6 |

| 6 | Replace the Print Head Does the product recover from nozzle clogging? | Print Head | End | Go to step 7 |

| 7 | Replace with a new Ink Cartridge and perform cleaning Does the product recover from the failure? | Cleaning | End | Escalate to person in charge |