Carriage Mechanism

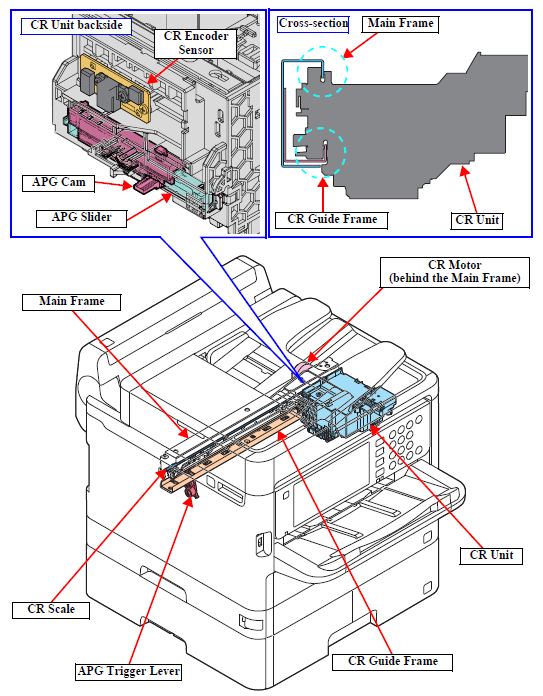

The carriage mechanism of this product consists of the CR Unit, CR Encoder Sensor, CR Scale, CR Motor, CR Timing Belt, etc.

Since the carriage mechanism moves the Printhead to the left or right to do printing, this is a critical mechanism that impacts printing quality.

As shown on the figure, the CR Unit is placed on the CR Guide Frame being the upperside of the unit held by the Main Frame.

The CR Unit is attached to the CR Timing Belt that is moved by the CR Motor so that the unit can move from side to side to print.

The position and speed of the CR Unit are always monitored by the CR Encoder Sensor and CR Scale, and the CR Motor is controlled in accordance with the information acquired by the CR Encoder Sensor.

The APG Mechanism adjusts the distance between the printhead nozzle and the paper (PG: Platen Gap) as suitable, depending on the paper to be printed.

The APG Mechanism of this product is equipped with an APG Cam placed between the CR Unit and CR Guide Frame, and simply changes PG just by the movements of the APG Trigger Lever and CR Unit.

Shifting PG (APG Mechanism)

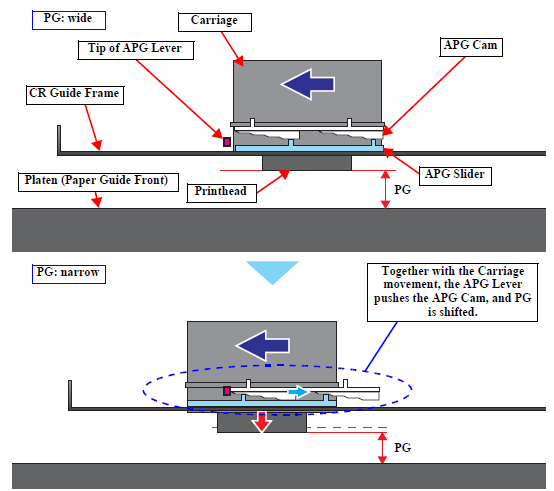

This product's APG Mechanism shifts PG with the APG Cam mounted on the Carriage.

APG Cam is located between the CR Guide Frame and the Carriage, and has a stepped cam face.

With the APG Lever applied, if the Carriage moves toward the APG Lever, the lever pushes the APG Cam, and the cam face of the APG Cam in contact with the APG Slider is shifted.

This action shifts PG.

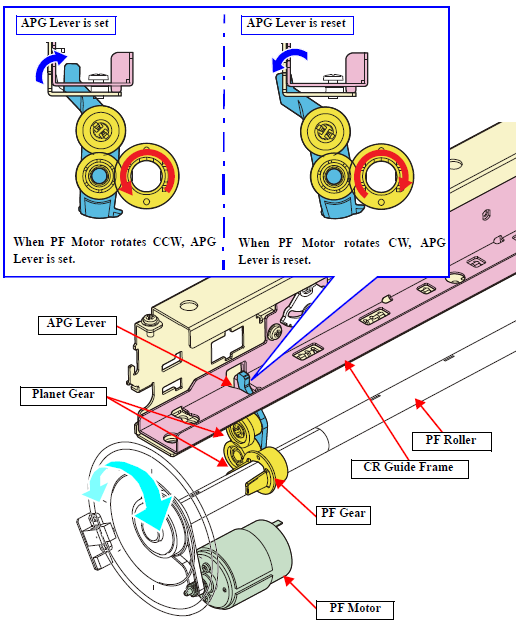

APG Lever actions

The PF Motor drives the Planet Gear, operating the APG Lever, and this sets or resets the APG Lever.

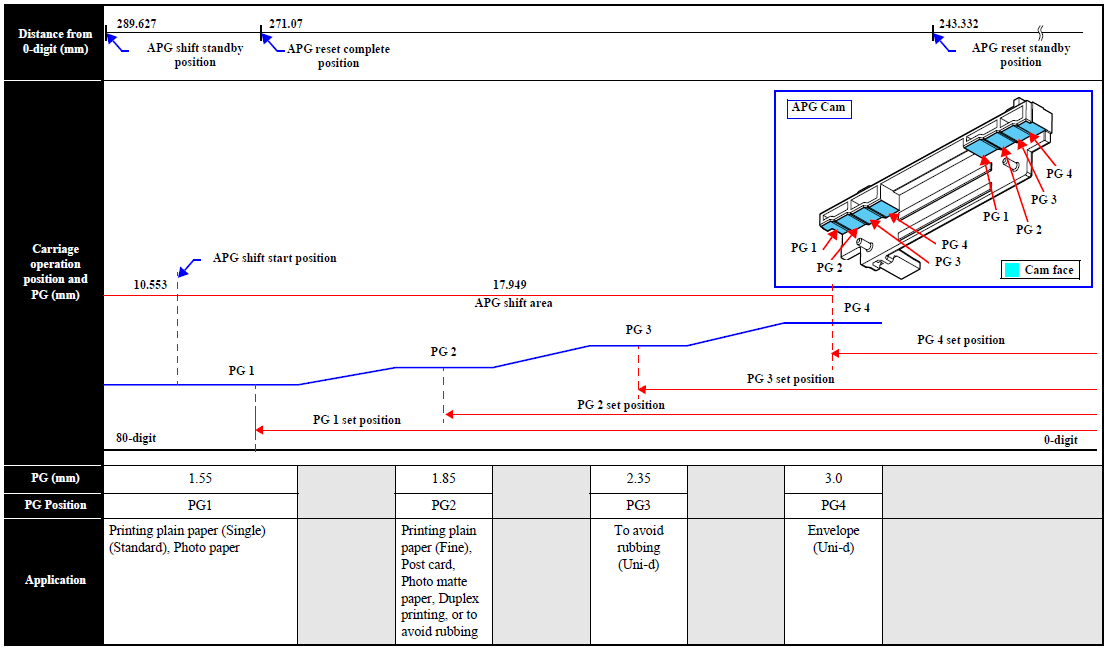

PG type

This product has four types of PGs. The following describes the details of PGs.

Each PG is determined by up to where the Carriage moves with reference to the APG Lever. PG set once is held until the next PG shift sequence.