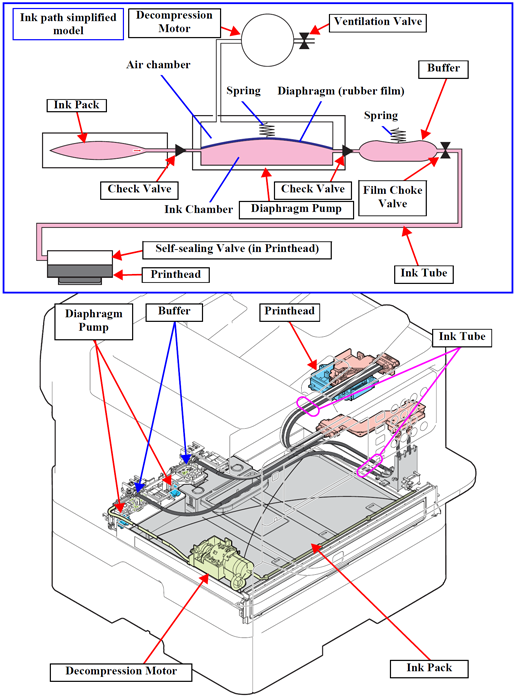

Ink Supply Mechanism

The ink supply mechanism consists of the Ink Supply Unit that is composed of the Ink Supply Tube, Diaphragm Pump ,Buffer, and Decompression Motor, and ink is supplied from the ink pack installed in the lower part of the product.

According to the quantity of ink discharged from the Print Head, ink is sucked from the ink packs by the Decompress Pump Unit, Diaphragm Pump and Buffer.

The ink path from the Buffer through the ink tube to the selfsealing valve in the Printhead is always kept pressurized even after the power is turned off by the check valves and the Diaphragm Pump.

Therefore, ink can be supplied stably during high-volume printing.

Operating principles

Ink supply becomes ready by installing the ink pack into the Ink Pack Unit in the lower part of the product.

The Ink Pack Unit also mounts the CR Contact Module to detect the remaining ink amount in the ink pack.

The diaphragm is operated when the Decompress Pump Unit reduces the pressure inside the Diaphragm Pump, and it sucks ink from the ink packs. Ink is supplied through the Buffer and ink tube to the Print Head.

The Decompress Pumps and Diaphragm Pumps supply sufficient ink needed for the quantity of the Prinhead's ink discharge in high speed printing with high image quality.

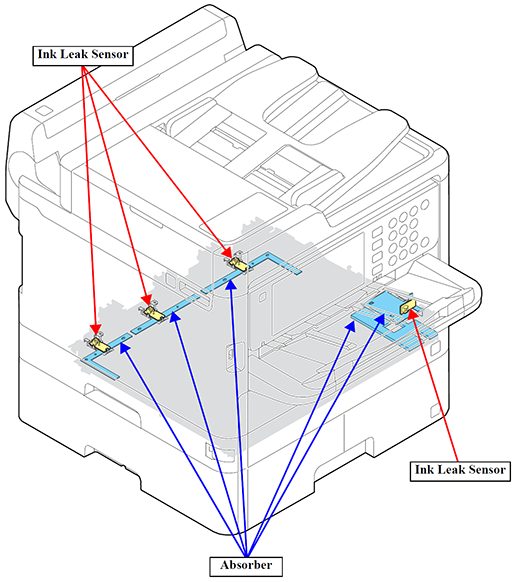

Ink leak detection function

Sensors for detecting an ink leak are provided in this product in order to enable the quick detection of an ink leak when an ink leak occurs from the ink supply path due to an abnormality in the product.

Ink Leak Sensors are provided inside the Ink Pack Unit, and detect an ink leak by the adherence of ink on it (Porous Pad Cap Lower) when an ink leak occurs. It also generates an ink leak error in the printer.