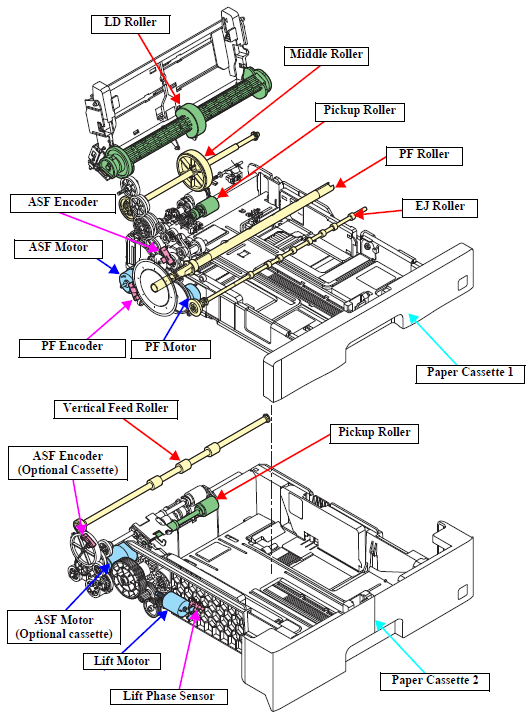

Paper Loading/Paper Feed Mechanism

The components of the paper loading mechanism and the loading method are as follows.

| Mechanism | Power source and control | Function | |

|---|---|---|---|

| Front paper loading | Standard Cassette (Paper Cassette 1) | Power source

Control

| Drives the Pickup Roller, loading paper from the Standard Cassette. Paper loaded from the Cassette is fed to the PF Roller using the Middle roller of the Rear unit. |

Optional Cassette (Paper Cassette 2 to 4) | Power source

Control

| ASF Motor (Optional Cassette)

Lift Motor

ASF Motor

| |

| Rear paper loading | Power source

Control

| Drives the LD Roller and Hopper of the Rear ASF Unit, loading paper from the Rear ASF Unit. | |

| Paper feed | Power source

Control

| Drives the PF Roller/EJ Roller, loading and outputting paper. | |

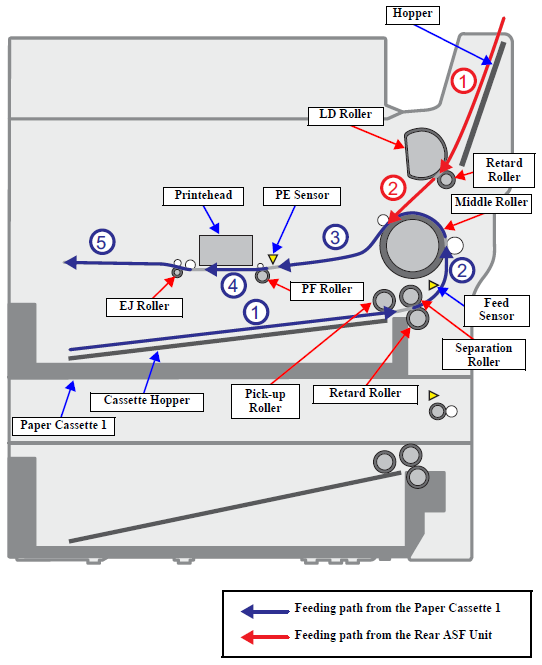

Paper Loading/Feed Path

Feeding from the Paper cassette 1

- When you set Paper Cassette 1 in the printer, the Cassette Hopper is lifted up by the pickup mechanism provided in Paper Cassette 1.

The paper set in paper cassette 1 is lifted up by the Cassette Hopper, and comes in contact with the Pickup Roller. - The ASF Motor is driven, and the Pickup Roller conveys paper to the Separation Roller.

The paper conveyed to the Separation Roller is separated from the second paper by the Separation Roller and Retard Roller, and is conveyed to the Middle Roller after passing through the position where paper is detected by the Feed Sensor. - The paper conveyed to the Middle Roller is conveyed by the Middle Roller up to the position where paper is detected by the PE Sensor.

- When the PE Sensor detects the paper, skew removal is performed in accordance with the printing conditions.

After the completion of skew removal, the paper is conveyed to the printing start position by the PF Roller, and printing starts. - After the completion of printing, the paper is extracted by the PF Roller and EJ Roller.

Feeding from the Rear ASF unit

- When printing is performed from the rear paper feed device, the drive transmission of the ASF Motor is switched by the Rear ASF Solenoid, and the LD Roller rotates by the ASF Motor.

- The paper set in the Hopper is conveyed to the Middle roller by the hopper-up action of the Hopper + LD Roller.

- The paper conveyed to the Middle Roller is conveyed by the Middle Roller to the position where paper is detected by the PE Sensor, and printing is performed in the same way as the Front Cassette.

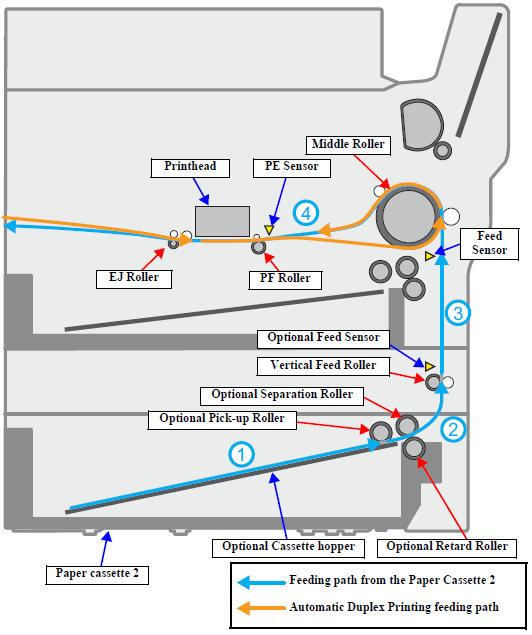

Feeding from Optional cassette (Paper Cassette 2 to 4)

- The drive of the Lift Motor is transferred to the optional hopper-up mechanism parts, which lifts up the Optional Cassette Hopper, and the paper set in Paper Cassette 2 comes in contact with the Optional Pickup Roller.

- The ASF Motor is driven, and the Optional Pickup Roller conveys paper to the Optional Separation Roller.

The paper conveyed to the Optional Separation Roller is separated from the second paper by the Optional Separation Roller and Optional Retard Roller, and is conveyed to the Vertical Feed Roller. - The paper conveyed to the Vertical Feed Roller is passed through the Optional Feed Sensor by the Vertical Feed Roller, and is conveyed up to the position where it is detected by the Feed Sensor of the printer.

- When the Feed Sensor detects a paper, the ASF Motor is driven, the paper is conveyed by the Middle Roller up to the position where it is detected by the PE Sensor, and printing is performed in the same way as the front cassette paper feeding.

Feeding path during the Automatic Duplex Printing

When automatic duplex printing is performed, an automatic judgment function for the drying time of the printed surface after surface printing is provided in order to avoid friction of the printed surface.

If drying is determined to be necessary after surface printing, two-stage printed surface drying wait is performed at two locations, namely on the Stacker (when the paper is held by the PF Roller and the Driven Roller) and inside the Rear Unit (when the Middle Roller has held the end of the paper).

Detail of Paper Loading/Feed Mechanism

Printer Main Unit

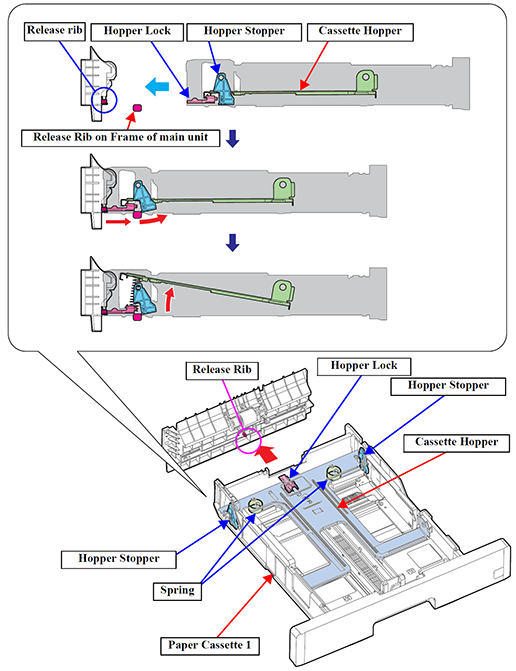

Lift-up mechanism

This mechanism lifts up the paper set in the paper cassette up to the paper pickup position by the pickup mechanism.

The lift-up mechanism operates the Cassette Hopper by the force of the spring provided inside the Paper Cassette.

When the Paper Cassette has been removed from the printer, the Cassette Hopper is locked by the Hopper Lock present in the center part and the Hopper Stopper on the left and right sides.

When you set the Paper Cassette in the printer, the Hopper Lock and Hopper Stopper of the Paper Cassette come in contact with the Release Rib, and the lock is released.

The released Cassette Hopper rises due to the tension of the spring.

Front Feeding Mechanism

The front feeding mechanism is composed of the Pick-up mechanism and the intermediate feeding mechanism.

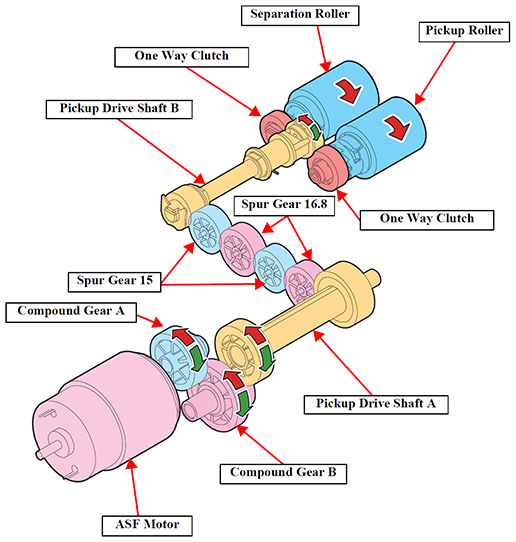

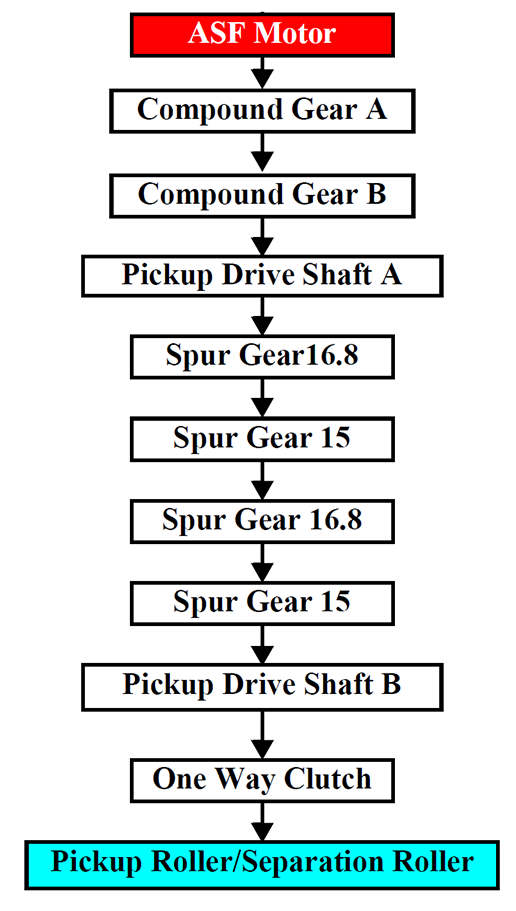

- Pick-up mechanism

This mechanism picks up paper from the Cassette Assy and feeds it up to the intermediate feeding mechanism.

The retard separation method is used for paper separation.

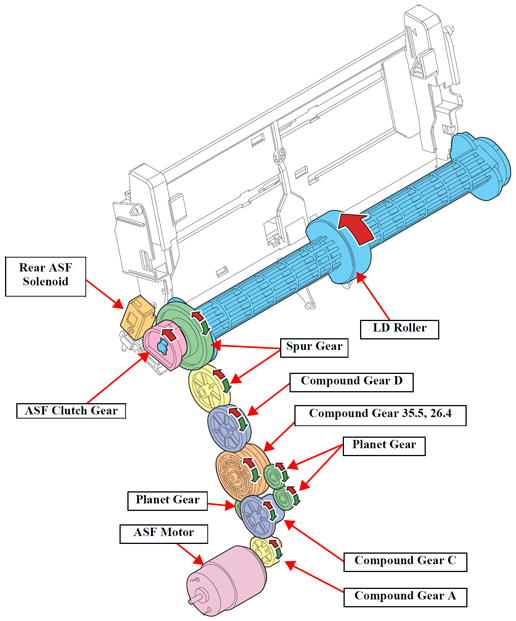

The ASF Motor drives the pick-up mechanism.

The pickup roller and separation roller uses a oneway clutch to always rotate in a set direction (paper feed direction) only. When the ASF Motor rotates the opposite direction of paper feeding, the drive force is cut off by the One Way Clutch, so neither the Pick-up Roller nor Separation Roller rotates.

(If it is not in the paper feed direction, it performs idling and no rotation.)

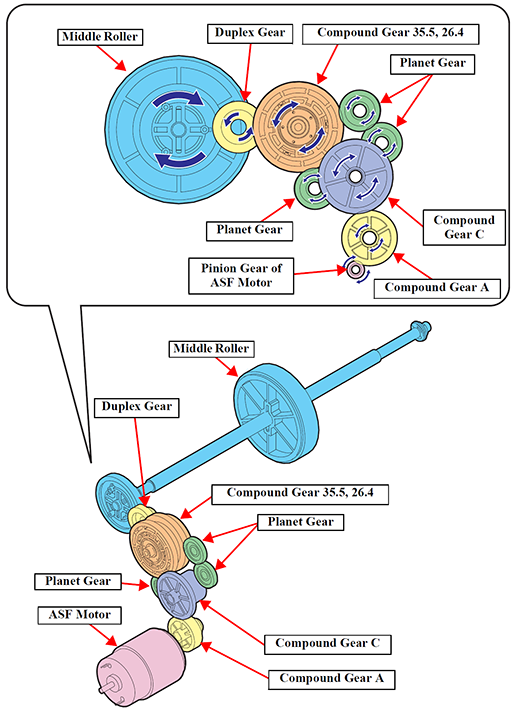

- Intermediate feeding mechanism

This mechanism feeds the paper fed from the Cassette Assy to the paper feed mechanism.

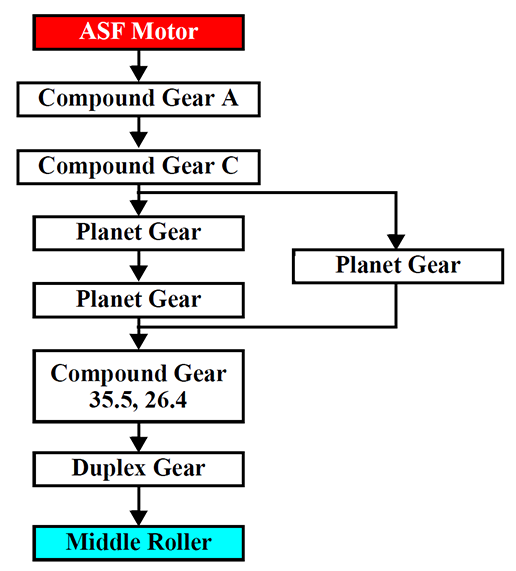

The intermediate feeding mechanism is driven by the ASF Motor.

The Middle Roller always rotates in a set direction (paper feed direction) because of the Planet Gear, regardless of the ASF motor rotational direction.

Rear Feeding Mechanism

This mechanism feeds the paper set on the Hopper to the intermediate feeding mechanism.

The retard separation method is used for paper separation.

The rear feeding mechanism is driven by the ASF Motor.

Since the ASF Motor drives the pick-up mechanism and intermediate feeding mechanism, the ASF Clutch Gear and Rear ASF Solenoid Assy turn the drive force ON/OFF so that the LD Roller rotates during the rear feed only.

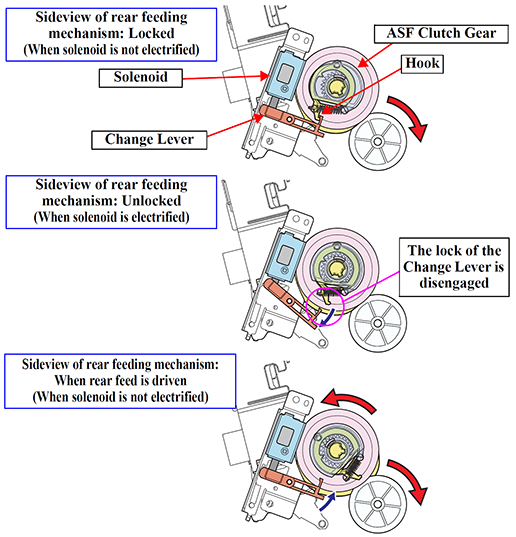

- Operation of the rear feeding mechanism

Drive force control by the ASF Clutch Gear and Rear ASF Solenoid Assy

The Rear ASF Solenoid Assy controls the operation of the Change Lever by electrifying the Solenoid. *

The relationship of the electrifying status of the Solenoid and the status of the Change Lever is as follow.Electrifying status of the Solenoid Electrified Not electrified Change lever Unlocked Locked When the Change Lever engages with (or locks) the hook on the ASF Clutch Gear, the clutch of ASF Clutch Gear is cut off and the ASF Motor's drive force is not transmitted to the LD Roller.

When the Change Lever releases (unlocks for driving the rear feeding) the hook on the ASF Clutch Gear, the clutch of ASF Clutch Gear engages and the ASF Motor's drive force is transmitted to the LD Roller.

*: Equipped with a pull type Solenoid in which the magnetic body id pulled by the electromagnetic force.- When performing the rear feed

When the printer starts performing the rear feed, the Solenoid of the Rear ASF Solenoid Assy is electrified and the Change Lever is moved down to unlock the hook.

Then the clutch of the ASF Clutch Gear engages and the drive force of the ASF Motor is transmitted to the LD Roller.

After the lock is released, the ASF Motor drives the ASF Clutch Gear and LD Roller to move the hook on the ASF Clutch Gear away from the lock position.

Therefore, when electrifying the Solenoid is stopped and the Change Lever is back to the original position, the hook on the ASF Clutch Gear is positioned lower than the Change Lever due to the rotation of the LD Roller and not going to be locked again.

After electrifying the Solenoid is stopped, the ASF Motor rotates clockwise further and the LD Roller rotates in the paper feed direction.

A sheet of paper set on the Hopper is separated by the LD Roller and Retard Roller and fed to the intermediate feeding mechanism.

When the LD Roller rotates once, the Change Lever engages with the hook on the ASF Clutch Gear and the roller is locked.

Then, the ASF Motor's drive force to the LD Roller is cut off and the rear feed process is complete.*

*: The LD Roller is D-shaped. This shape allows the LD Roller and Retard Roller to release the paper when the paper reaches the intermediate feeding mechanism so as not to affect the paper feeding process of the intermediate feeding mechanism.

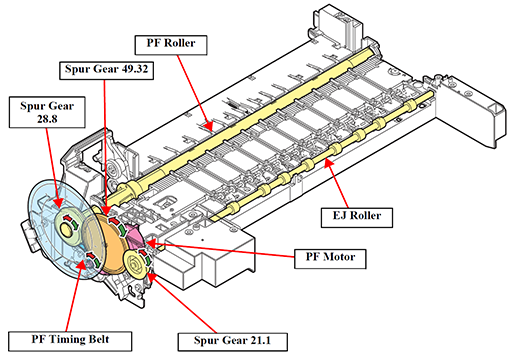

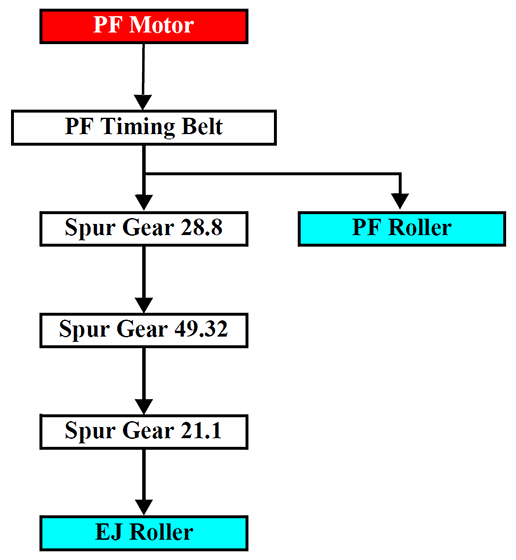

Paper Feed Mechanism

This mechanism feeds the paper fed from the intermediate feeding mechanism and ejects it.

The paper feed mechanism is driven by the PF Motor's drive force. The drive force of the PF Motor is transmitted by the PF Timing Belt to the PF Roller and EJ roller to perform paper feeding before/after printing.

Optional Paper Cassette

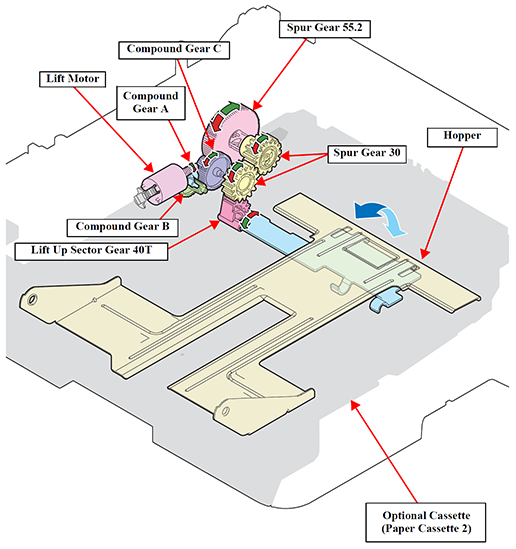

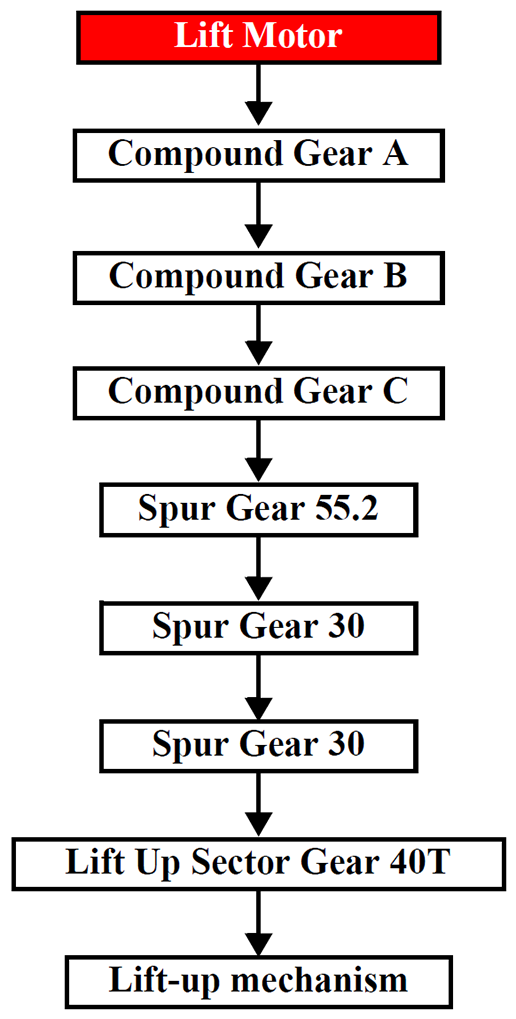

Lift-up mechanism (Optional cassette)

This mechanism lifts the paper loaded on the Paper Cassette 2 up to the paper pickup position.

This mechanism is driven by the drive force of the Lift Motor.

The Lift Motor's drive force is transmitted via the Lift-up Gear Group to this mechanism and rotates the Lift-up shaft.

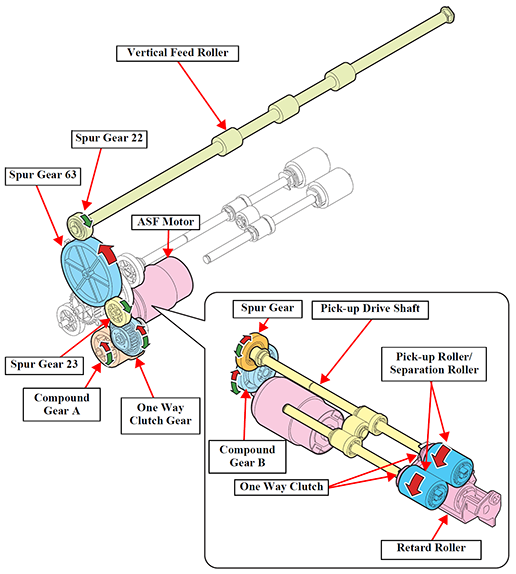

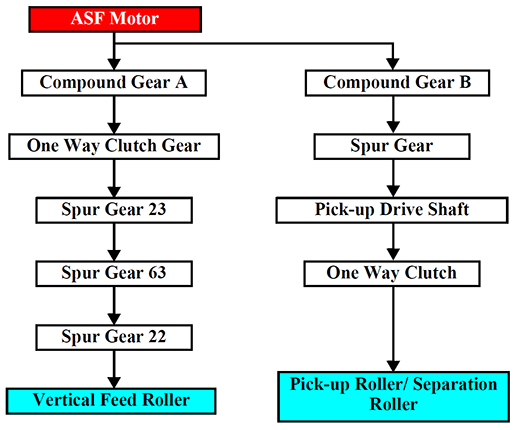

ASF Mechanism (Optional cassette)

This mechanism picks up paper from the Optional Cassette, and conveys it up to the intermediate feeding mechanism of the printer, and the same retard separation method as that for the Paper Cassette of the printer is adopted.

The ASF mechanism is configured by the pickup mechanism and the intermediate feeding mechanism, and operates by the driving force of the ASF Motor.

- Pick-up mechanism

On the shafts of the Pick-up Roller and Separation Roller, the One Way Clutch is mounted to always rotate in a set direction (paper feed direction) only. When the ASF Motor rotates the opposite direction of paper feeding, the drive force is cut off by the One Way Clutch, so neither the Pick-up Roller nor Separation Roller rotates.

(If it is not in the paper feed direction, it performs idling and no rotation.) - Intermediate feeding mechanism

A One Way Clutch Gear is provided in the middle of the drive path in the intermediate feeding mechanism, and the Vertical Feed Roller rotates in only one fixed direction (paper feed direction).

(If it is not in the paper feed direction, it performs idling and no rotation.)