Preparing the thickness gauge

Caution / 注意 Caution / 注意 |

|

Application procedure of Teflon tape

- Clean the surfaces of the thickness gauge by using alcohol, and make sure no dirt or contamination remains on the surfaces.

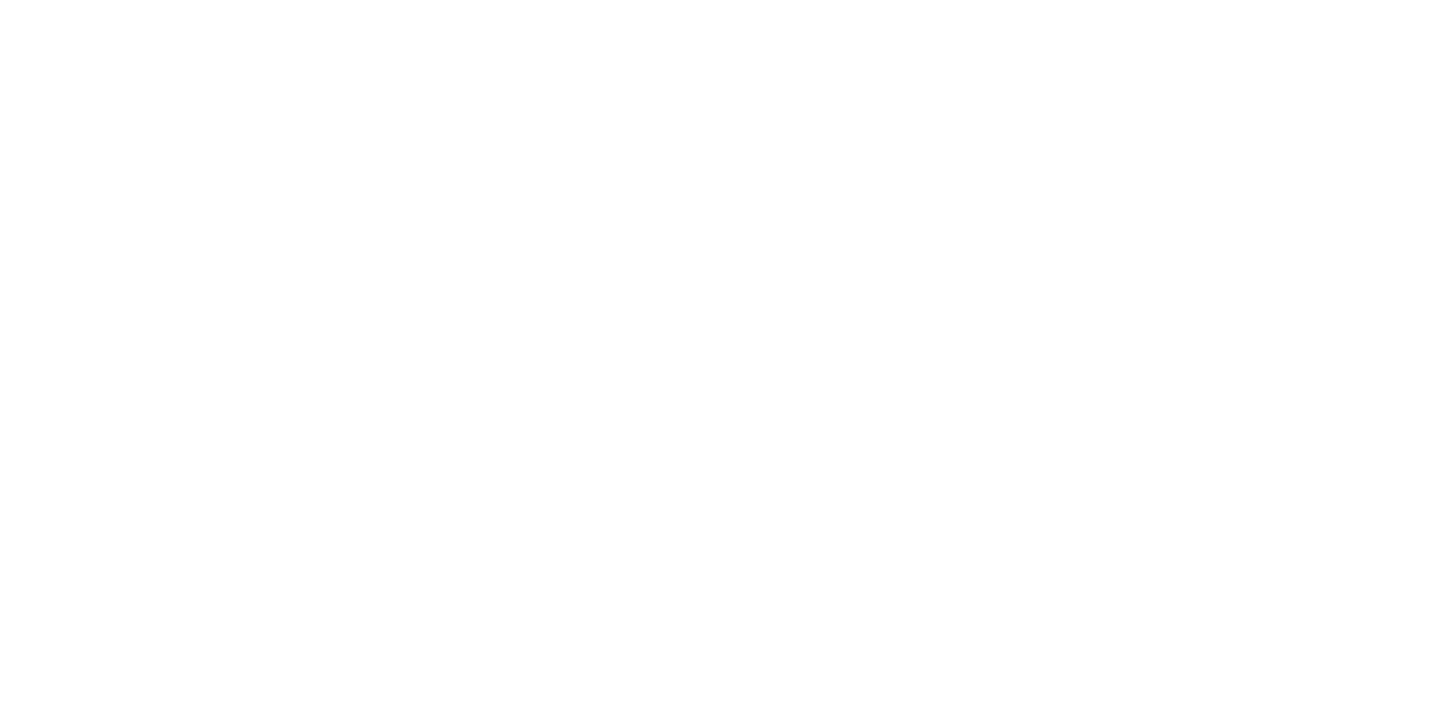

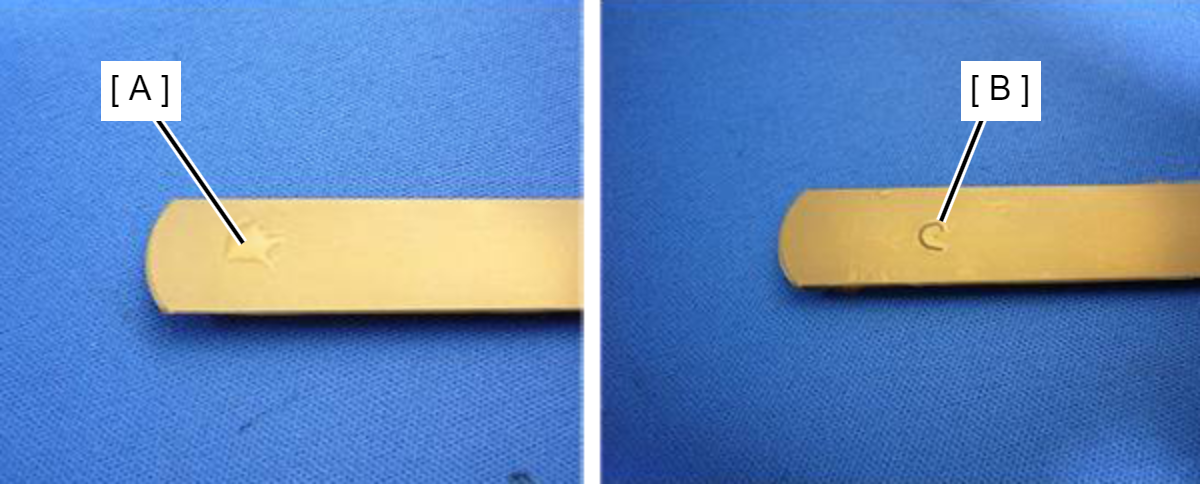

- Apply Teflon tape (B) on the thickness gauge (A) as shown below.

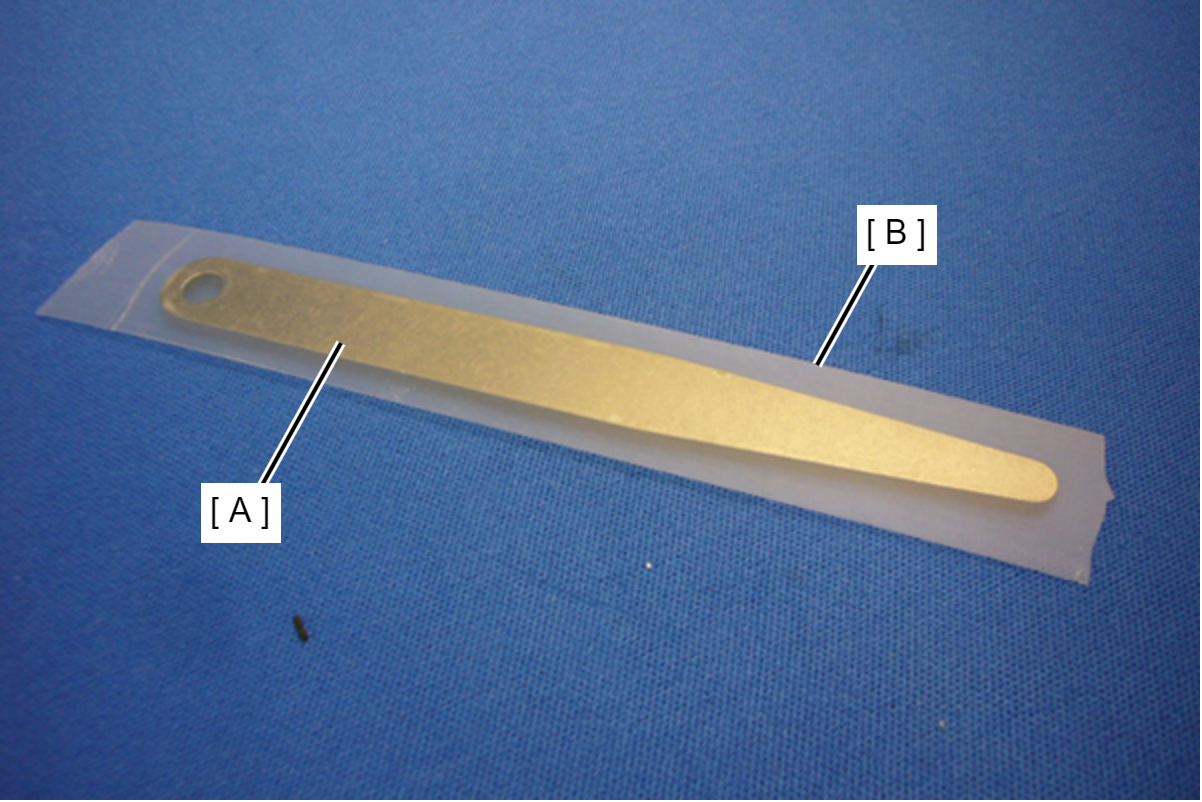

Fold the excess portions of Teflon tape (A) along the edges of the thickness gauge (B), and trim the portions at about the center in the thickness direction of the sides.

- C: Before trimming

D: After trimming

Check Point / チェックポイント

Check Point / チェックポイントWhen trimming the Teflon tape, the Teflon tape can be easily cut out by using a thickness gauge of roughly half the thickness as guide for the cutter.

Caution / 注意

Caution / 注意- Make sure to wear the heavy gloves to prevent the cutter from cutting the hand when trimming the Teflon tape.

- When trimming, cut in the opposite direction, away from the hand holding the gauge.

Make sure there are not any tears or burrs on the applied Teflon tape, then the preparation of thickness gauges is complete.